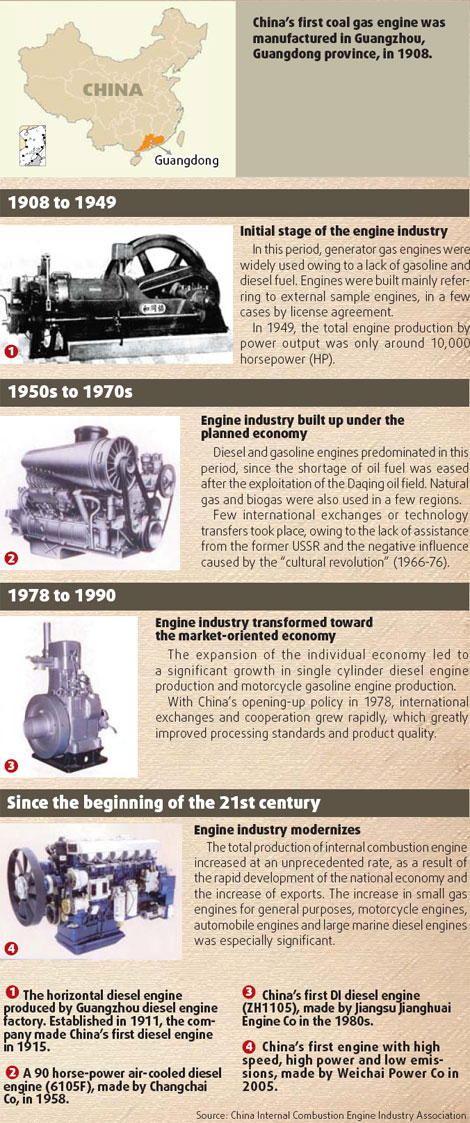

China's first coal gas engine debuted in 1908, and 100 years later the country has become one of the world's leading engine producers.

Occupying about one third of the world's internal combustion engine output, the industry in China is composed of 1,300 domestic enterprises engaged in engine, spare parts and accessory manufacturing. In 2007, China's total engine production was 57 million units, including an export amount of over 10 million units, and the total power exceeding 1 billion KW.

It's estimated that China's engine production will reach 60 million units in 2008, with the total power output of 1.1 billion KW.

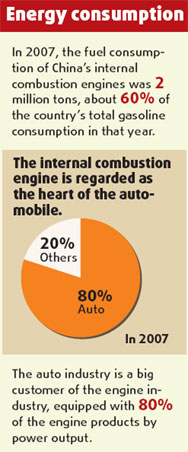

According to statistics, since 2000, the fuel consumed by engine-driven vehicles has occupied 50 percent of the country's total diesel consumption and one third of the total gasoline consumption.

Meanwhile, in China's big metropolises, more than 80 percent of the carbon monoxide, 40 percent of the nitrous oxide, and 20 to 30 percent of the particulate matter, are from motor vehicles.

To improve the efficiency of China's internal combustion engines, the country's authorities have designed several standards and regulations to reduce the pollutants.

Since 2007, all kinds of vehicles all over the country have begun using fuel that meets the China III emission standards. In March 2008, Beijing took the lead in implementing new China IV emission standards. Responding to the trend, new engines have been developed to meet the new, more stringent emission standards.

As in Western countries, China's newer internal combustion engines have become technology-intensive products that integrate with electronic controls and catalytic technology.

For China's diesel engines, techniques such as common rail, electronic unit-pump, multi-valve, exhaust gas recirculation and variable geometry turbochargers have been widely used.

For the country's gasoline engines, Western engine technologies have been adopted such as multi-valve, dual overhead camshafts, charger intercoolers, variable geometry induction and dual-spark plug ignition. Engines with variable valve timing have been popular models. Domestic companies with self-designed and owned gasoline engines have developed some modern techniques as well, including turbo charging and variable valve timing.

With the progression of China's reform and opening-up policy, many technology transfer projects took place involving joint ventures or external wholly-owned entities producing advanced engine models by advanced processing methods and imported machine tools.

Yet, the core technology can hardly be mastered simply through technology transfers or technical cooperation, in certain cases even special restriction clauses were stipulated in the contracts. The core technique of diesel engines - electronic controlled common rail system - is still mastered by multinational companies. For developing new products, domestic companies mainly rely on the support of world's leading multinational companies such as AVL, FEV and Ricardo.

The situation is changing gradually. According to figures from China's State Intellectual Property Office of China, the number of patents related to internal combustion engines is almost 5,900 now, nearly 10 times the number 10 years ago.

Advanced Western engine technologies, including adiabatic ceramic, cylinder cut out control, intelligent valve and variable compression ratio, have drawn the attention of some domestic companies and scientific research institutions and some have already begun developing these techniques.

According to some industry experts' predictions, about 15 percent of vehicles will be equipped with diesel engines by 2015 and the proportion can be increased to about 30 percent by 2020.

Tan Xuguang, director general with China Internal Combustion Engine Industry Association, says: "For further boosting the development of self-owned brands, it's necessary to build up the national technique standard on the production of internal combustion engines, instead of continuing to use regulations from Europe. China aims to achieve the goal of being one of the globe leaders in engine technology by 2020."

(China Daily 10/27/2008 page7)