|

The $2.9 billion Nanjing integrated site is BASF's largest single overseas investment in its 140-year history. |

"Honeybee" is the word Johnny Kwan uses to describe his company.

As the chairman of BASF Greater China Country Board, Kwan is leading the company's efforts in environmental protection and corporate social responsibility (CSR).

"In the process of honey making, a honeybee is continuously spreading pollen, which will enrich the environment. Then with the pollen more flowers will blossom, and more honey will be made, so everybody is winning," Kwan tells China Business Weekly.

"In BASF, we are working hard not only to benefit ourselves, but also our stake holders, as well as the industry and the environment," he says.

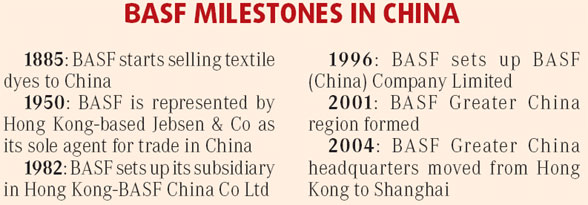

The German chemical maker originally started its trade with China in 1885. Today, it has become one of the leading foreign investors in the Chinese chemical industry.

With over 6,000 employees in China, BASF currently operates 23 wholly owned subsidiaries and 10 joint ventures in the country. The company's portfolio in China now ranges from chemicals and plastics to agricultural products.

Today China is the company's third largest market, after Germany and the United States. Last year, the company achieved sales of about 4.4 billion euros in the Chinese market.

China is also BASF's fastest growing market globally. "Over the last four years our business has increased three-fold in the country," says Kwan.

Grow with China

BASF products have entered China for more than 100 years. As early as in 1904, China already accounted for 7 percent of BASF's global sales, with then synthetic indigo as the company's key product.

In 1950, the company was represented by Hong Kong-based Jebsen & Co as its sole agent for trade in China.

Realizing that China's importance as a market, BASF in 1982 set up its own subsidiary in Hong Kong, with the name of BASF China Co Ltd.

In the 1980s the company started to set up joint ventures with Chinese partners to expand its presence in the country.

In the early 1990s, the company came up with its "Vision 2010", saying that by the year, 20 percent of the company's global sales will come from Asia Pacific.

"What is important in the vision is that half of the 20 percent will come from China," says Kwan.

"What's more, in the Asia-Pacific region, our target is that 70 percent of the sales will come directly with locally-produced goods, and this also applies to China," he says.

With this vision the company started several big manufacturing projects in China. In December 2000, BASF and Sinopec established a joint venture company, to build and operate an integrated petrochemical site in Nanjing, capital of Jiangsu province.

Total investment in the project was $2.9 billion and BASF holds a 50 percent stake. It is the company's largest investment in China, as well as its largest single overseas investment in 140 years of history.

At the core of the integrated site is a steam cracker supplying nine world-scale downstream plants. The site can produce about 1.7 million tons of chemicals and polymers per year. All plants began commercial operations in mid 2005.

Following its successful operation both Sinopec and BASF agreed to expand this joint project, with an additional investment of $900 million. New facilities will come on-stream starting in 2008.

"The Nanjing integrated site has used BASF's most advanced technology. With production in the integrated site, we can save a lot of raw materials and energy, and also centralize our waste treatment and environmental protection," says Kwan.

"Globally we have six such integrated sites. We can realize about 800 million euros of savings each year from these six sites."

Apart from the Nanjing project BASF also expanded its production facilities in other regions in China. In mid 2006 the company's second biggest project in China, an integrated isocyanates complex started commercial production, with the total investment of $1 billion.

In China, BASF is quickening its pace in research and development (R&D). It has set up a number of technical centers to improve the company's technology to better suit customers. These centers cover a lot of areas, ranging from automotive gear and footwear to lady's skin care.

The company is also paying a lot of attention to basic research. Started in 1997, the BASF Sino-German R&D fund has supported collaborations with Chinese universities and relevant institutes through grants and scholarships.

"Until now we have been running over 50 research projects under the fund, covering fields like macromolecule material science, organic compounds, industrial catalyst research, nanotechnology and biotechnology," says Kwan.

Future development

Looking into the future, Kwan says, "organic growth and mergers and acquisitions (M&A) are equally important to BASF in China".

Besides a lot of investment in East China, the company is seriously considering making a major investment in the West in Chongqing, to produce MDI, an important chemical raw material.

In some businesses, BASF is also looking for M&A opportunities. For instance, in 2006 the company acquired domestic concrete additives producer, Hi Con.

China's construction chemicals industry is growing very fast. The company will take advantage of this to better develop the business, says Kwan.

In the past few years, BASF acquired some companies globally. It bought Degussa's construction chemicals business, acquired Johnson Polymer, as well as the catalysts producer Engelhard.

In China, any M&A deals must match the company's overall strategies, which is to better serve the customers and the environment, he says.

With Chinese government putting more emphasis on the environment, the country's chemical industry will see healthier growth in the future, says Kwan.

"In BASF, we are not only doing environmental protection by ourselves, we are also promoting it in cooperation with the Chinese government and the industry authorities," he says.

(China Daily 05/26/2008 page6)