Living in a straw dwelling doesn't necessarily equal to living in a primitive hut. It can be a 21st century eco-friendly modern abode.

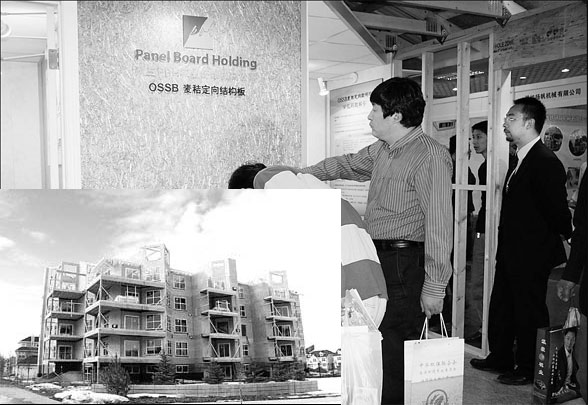

In an expo showcasing the benefits of straw and stalk housing on May 9-11 in Beijing, a home made completely of wheat straw, attracted many visitors as an advanced and eco-friendly solution to treat hundreds of thousands of tons of the agricultural harvest waste every year.

The house was built with a material called oriented straw structure board (OSSB).

Straw tubes are split horizontally into pieces at least 4 cm long. Three layers are compressed together with an environmental-friendly adhesive free of formaldehyde.

The composition of wheat or rice straw is similar to wood. The abundant cellulose and lignin in straw and stalk can also replace wood materials for panel production, as scientific and technological examinations have proved.

Panel Board Holding (PBH), a company headquartered in Hague, Netherlands, produced the house. The company is working with the Alberta Research Council of Edmonton, Canada, to develop agricultural fiber-based technology.

Now PBH has brought the technology of making construction and package materials from crop straws to China.

The Shaanxi Global Jiahe Panel Board Co Ltd, a joint venture invested by Xi'an Huaheng Technology Industrial Co Ltd and PBH Company of Netherlands, was opened last year. The total investment reached 220 million yuan.

The company is using the 2008 harvest season to start its business in China.

It is located in the Hongqing Industrial Park in Baqiao District of Xi'an and an OSSB production line has been designed and built.

The annual production capacity of its production line is 60,000 - 80,000 cu m. Estimated roughly, the project can consume 40,000 tons of wheat straw, which supports the local government's efforts to increase the development and utilization of crop straws.

Yu Lei, a representative of PBH Beijing, says: "In cooperation, PBH provides funds and fiber-based technology, while Huaheng, the local business partner, is in charge of collecting straw from farmers nearby Xi'an."

"Although crop straw is of little value, gathering a certain amount to meet the production needs is very difficult," Yu says. "But Huaheng has had fiber-based production for several years in Xi'an. It has established a network of collection."

Because building straw houses is not in line with China's current real estate development, the joint venture company will focus on production of construction and interior decoration panels, as well as package materials, according to Yu.

The technology of using crop refuse will help the country not only save its natural resources, but also protect its environment.

Figures showed that in 2005, the country lacked 26 million cu m of timber to meet its needs and had to rely on imports. And it is estimated that in 2015, the gap will reach 90 million cu m.

The company in Xi'an with an annual production of 60,000 cu m of panel boards can be served to substitute 70,000 cu m of timber, which will prevent 12,000 hectares of primary forest from being cutting.

Besides protecting forestry resources, straw panel board provides China with a green solution to treat its agricultural waste.

China is a big agricultural-producing country. In 2007, figures from the National Development and Reform Commission (NDRC) showed that the country produced more than 500 million of tons of food.

Roughly estimated, 1 ton of corn can leave over about 2 tons of straw waste, and 1 ton of rice or wheat can produce a similar amount of straw and stalk. Every year, the country has to dispose of more than 650 million tons of crop refuse piled on the farmland.

Statistics also show that each year more than 200 million tons of harvest waste is burned by farmers to clear land and to put nutrients back in the soil. The traditional technique not only wastes resources but also causes air pollution and other problems.

For example, last June, Beijing recorded the worst air quality in the past seven years, as it was substandard for 15 days in the month.

Air particle pollution was the worst offender, said officials with the Beijing Municipal Bureau of Environment Protection. The pollution was mainly caused by car exhaust, while farmers burning stalks in neighboring Hebei, Henan, Shandong, Jiangsu and Anhui provinces were also to blame, the Beijing officials said.

And last September, in Jinan, east China's Shandong province, due to heavy smoke caused by straw burning, 14 commercial air flights had to be postponed in the morning.

Recently, to prevent Beijing from being choked during the coming Olympic Games, China released a five-month prohibition on burning farmland agricultural leftovers.

The Ministries of Environmental Protection and Agriculture jointly issued a no-burn edict for farmers from May to September, in regions around Beijing including Tianjin municipality, and the provinces of Hebei, Henan, Shandong, Shanxi, Anhui, Jiangsu and Liaoning.

The ministries urged local farmers and companies to recycle the agricultural waste and develop businesses in the fields of power generation, biomass production and construction material production.

Studies show that if 650 million tons of straw is burned, the heat produced during combustion is equivalent to 300 million tons of coal equivalent.

However, some analysts say because of the high cost of research and development and difficulties in the collection, storage and transportation, the business of recycling the agricultural refuse isn't rosy.

Working out an effective policy and mechanism to ensure the quantity and quality of straw and stalk is also needed, Yu says.

(China Daily 05/26/2008 page5)