The Swedish-based Sandvik group, one of the world's largest engineering equipment producers, plans to expand its manufacturing production bases on the Chinese mainland this year to tap the nation's mining and construction boom.

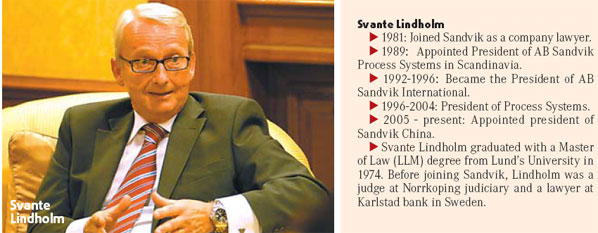

Sandvik China is set to build three new factories in Wuxi, Jiangsu province, to enhance its production capacity, Svante Lindholm, president of Sandvik China Holding Co, tells China Business Weekly.

The three factories, operated by the company's three business sectors: Sandvik Mining & Construction, Walter, and Sandvik Hard Materials, will respectively produce cemented carbide tools for mining equipment; design and produce cutting tools and special tools; and produce cemented carbide wear parts.

The factories will start construction in October, the company says.

In addition, the company also plans to expand its production lines for mining equipment crushers in Jiading of Shanghai this year.

"The new production lines will mainly serve the Chinese market, and the secondary purpose is to serve Asian market and exports," said Svante.

Sandvik notched up 3.8 billion yuan sales revenue in China last year, a 20 percent year-on-year growth. While sales from mining equipment business grew the fastest among all its three business sectors.

The Swedish firm specializes in three major business sectors: tools, which cover tools and tooling systems for metal cutting and components; mining and construction which provides equipment, tools and services for mining and construction; and material technology, which focus on stainless steel and special alloy products for niche applications, resistance materials and steel belt process systems.

As a drilling equipment provider, Sandvik sees opportunities in China's new round of mining exploration as a strong stimulus to drive their profit growth. The recent price hikes of some core mining crude products including iron ore and coal are luring many investors rush to explore new mines.

The Sweden-listed company reported SEK 86 billion ($14.6 billion yuan) global income last year, on which net profit hitting SEK 14.39 billion (2.45 billion yuan).

China ranks as Sandvik's No 8 regional market in terms of revenue and employers, according to Sandvik's 2007 fiscal report.

However, Lindholm expects China's global rank will be higher in the upcoming years.

Sandvik entered China in 1985, and currently has 1,500 staff, and 7 manufacturing plants across the country.

Its first industrial plant in China is located in Langfang, southern Beijing, which mainly produces cemented-carbide tools.

Lindholm, who became Sandvik China president in 2005, pointed out that the biggest challenge for Sandvik, a technology-intensive company, is "how to nourish a pool of human resources".

As a stimulus to attract and retain the employees, Sandvik China recently initiated a corporate pension plan and has signed the corporate pension plan agreement with Taiping Pension Co which help invest and operate the fund and the account manager China Merchant Bank late last month.

Under the plan, the company and each of their employees will each contribute 7 percent and 1 percent of the staff's wage every month to their pension fund pool.

So far, the plan has covered 97 percent of the company's 1,500 contracted Chinese staff.

"It takes us years and years to train laborers, and they are assets that are much more valuable than anything else," says Lindholm.

As the new labor contract law came into effect, many labor-intensive foreign-invested enterprises are reported withdrawing from the Chinese mainland to countries with a cheaper labor pool in anticipation of slimmer profit margins due the rising costs.

However, Sandvik says the company has "a long-term commitment to China because of its people".

"We will not transfer our production base to anywhere else because of labor cost rise, definitely not," says Lindholm.

China's labor costs are still very competitive compared to elsewhere, says Lindholm.

"When we are selling our product, we are trying to sell not only products, but also productivity," says Lindholm. "In order to sell productivity, we need to have interaction, communication and a direct relationship with our customers, and that means we are in China".

(China Daily 04/28/2008 page6)