Johnny Kwan knows that more hands make hard work easier.

"Though we are a giant company, without support and cooperation with governmental departments, counterparts and partners, our efforts to promote environmentally friendly technologies, products and services would be rather fragile," says the chairman of BASF Greater China.

The Fortune 500 chemical giant says a high priority is establishing and expanding partnerships to economize on resource consumption and cutting emissions.

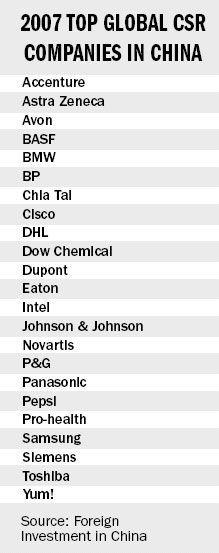

Due to its efforts in governmental programs and incentives for local partners, BASF was named one of the top global companies in CSR (corporate social responsibility) performance in China in 2007. The award was given late last month by the magazine Foreign Investment in China, which operates under the guidance of the Ministry of Commerce.

Governmental cooperation

Kwan says he applauds government's plans to build a resource-conserving, environmentally friendly society, goals that were reinforced during the recent 17th National Congress of the Communist Party of China.

"That is also BASF's commitment globally, including in China," he says, noting that with that approach, the German-headquartered chemical giant can play a more active role in the world fastest-growing market.

BASF recently further broadened its cooperation with a range of governmental departments to use its strength in research and development (R&D), utilizing both its technological capacity and professional talent.

In June, the company and the State Environmental Protection Administration (SEPA) signed a Memorandum of Understanding to increase cooperation on clean fuels by starting a diesel testing laboratory.

BASF and SEPA also co-sponsored a gasoline engine testing lab in 2005. In the new diesel lab, BASF supports the project financially and is providing technology and R&D expertise.

The two entities are working together at the lab to study and identify selected industries to undergo what is known as "eco-efficiency analysis" developed by BASF that looks at a product not in isolation but in the context of how it is used and in comparison with alternative products.

During the process, training, seminars and symposiums will be organized to disseminate knowledge of applications and management for the concept, according to Wu Xiaoqing, deputy minister from SEPA.

The company is also collaborating with the Shanghai Municipal Government on renovation of the city's Hongkou old house district and Tongji University's Wenyuan campus to enhance energy efficiency.

As one of the eco-building projects, the Hongkou renovation includes a 1980s-era building that has been coated with the company's polyurethane on its exterior walls and roof, which along with double-glazed windows and advanced electric heating, can reduce energy consumption by 70 percent.

The Tongji Wenyuan renovation project now underway will also use BASF's ecological and energy-efficient construction products.

"The eco-building partnership is a great opportunity for BASF to demonstrate how energy-efficient technologies and construction products are increasingly interlinked in a sustainable building," says Kwan.

SME partners

Governmental cooperation to help BASF introduce its advanced technologies and products to the Chinese market has been smooth, he says.

"Collaboration with our industrial partners, including suppliers, logistics companies and distributors, is really crucial, otherwise we cannot carry out our plans thoroughly and effectively," says the chairman.

Ninety percent of chemical businesses are small and medium-sized enterprises (SMEs) in China that are not mature enough to implement green concepts, so the company has begun what it calls a "one-plus-three" project to popularize environmental protection.

Under the model, BASF formed a team with three SME business partners. It then imparted CSR principles, including environmental responsibility, to the team by coaching on best practices and solutions based on its experience and expertise. The partners are then expected to pass on the model to three other business partners of their own.

Six partners have participated in the program since it began in October,

"BASF has taken an important step towards closer cooperation with stakeholders in the industry. This strong network serves as a tool to increase public awareness of the company's energy-efficient technologies and products," Kwan says.

In 2006, BASF had sales of over 3.6 billion euros on the mainland, Hong Kong, Macao and Taiwan. About seven percent of the company's global turnover and profit were from its chemical business in China. The company projects Chinese revenues will reach 10 percent of its total by 2010.

(China Daily 12/15/2007 page8)