Forging into the future

The centuries-old knife-making traditions of the Bonan craftsmen are surviving thanks to the close-knit community's spirit of competition and innovation, Fang Aiqing reports.

Ma Gazhuma, from Northwest China's Gansu province, is a man who "plays with fire" for a living.

The old and new scars on his arms and hands, and the burn holes in his overalls mark his triumph in mastering the over 800-year-old craft of the Bonan people and a national intangible heritage - knife forging.

Bonan is one of the smallest ethnic groups in China, and the majority of its members live in Jishishan Bonan-Dongxiang-Salar autonomous county on the border between Gansu and Qinghai provinces.

|

Craftsmen produce Bonan knives in a workshop run by Ma Gazhuma in Jishishan Bonan-Dongxiang-Salar autonomous county in Gansu province. It takes between 40 and 80 procedures to make one knife, depending on its design. Photos Provided to China Daily |

It takes between 40 and 80 procedures to make a single knife depending on its design.

The raw materials, mainly iron and steel, are easy to obtain, but the key to creating a typical Bonan knife lies in the repetitious process of hammering and quenching that demands decades of practice to master. The knife is made by pressing together sheets of iron and steel, melting them to over 1,000 C to form a bar, and then twisting and hammering it into shape.

It requires years of experience to learn how to gauge not only the intensity of the hammering, but also the position and angle to do it from. And for the quenching, the craftsmen need to judge the temperature of the fire by the color of its flame in order to achieve the appropriate rigidity. The way these knives are forged explains why there are no two Bonan knives with identical blades.

Ma, 40, is the fourth generation in his family to take up the craft. Every one of the knives they forge has the Chinese character xiong carved on it as their trademark. This is the last character of his late father's name, Ma Weixiong, who was recognized as a national representative inheritor of the craft in 2006. Their knives are well-known for the intricate patterns on their blades.

In 2007, the father and son spent a week at their old home in the mountains, burned 250 kilograms of coal, and took it in turns to do the hammering, before finally figuring out a method to forge a pattern they call the "Running Yellow River".

The pattern, which looks like a stream with tributaries, was described in a folk tale passed down through the generations - but hadn't been seen by anyone alive. Now, the lost art has been revived, and as the pattern's name implies, the Bonan call themselves the "people who live by the river".

The family also has a patent for a "spider pattern". The challenge in making it lies in keeping the pattern symmetrical.

Now, a knife forged by Ma Gazhuma, who was recognized as a national representative inheritor last year, can sell for more than 5,000 yuan ($708).

Bonan knives have always played an important part in the community. Historically, the people were weapon makers for the Mongol ruler Genghis Khan (1162-1227).

The knives present an auspicious spirit. Young couples keep a specially designed knife - formed by two blades in one scabbard - as a love token.

Ma Gazhuma has known many of his peers since childhood, and over the years, they have continued to learn from one another.

This common practice has now gained more recognition after the government launched a temporary workshop in January to teach the local people - including 25 underprivileged trainees - how to improve their forging skills. The trainees were paid whether they attended the workshop as novices or as longtime apprentices.

Ma Yisihagei, who has been in the field for decades and has to support a family of five on his own, joined the workshop to learn to make a completely different kind of knife to the ones he was used to. He also received a subsidized loan of 50,000 yuan to support his business last year. This will help him to earn over 30,000 yuan this year, about 10,000 yuan more than in previous years.

For generations, many Bonan families have also developed their own specialties, which has in turn helped to protect the industry as a whole while fostering an environment for friendly competition in the relatively close-knit community.

Ye Salihai, a fifth-generation practitioner who has enjoyed the title of a national representative inheritor since last year, is from another major knife-forging family known for making a kind of small, daily-use knife that got its name from its fish-head-like shape.

Some older Bonan men still shave using these knives.

There was a time when almost every family from Dahejia town in the county forged knives for a living and didn't have to bother about sales, says Zhou Yongxiang, a county official who leads the local cultural development efforts in the area. He had previously spent two years learning how to forge knives, but now, few of his peers remain in the field as sales have become a burden - Bonan knives cannot be taken on public transportation nor sent by post for security reasons, which has limited the market.

Knife makers and the local government have been struggling to find a way out of the situation. Many practitioners have turned to making kitchen knives and cleavers on the side. They are also exploring ways how to prevent the knives from rusting, and looking into replacing coal forges with electrically-powered ones.

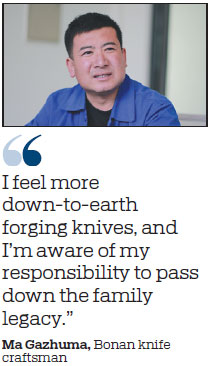

Ma Gazhuma, who started learning forging skills during childhood, tried his hand at working on construction sites - but he soon gave up.

"I feel more down-to-earth forging knives, and I'm aware of my responsibility to pass down the family legacy," he says.

His children are fond of playing with a little hammer after school, just like he was when he was their age.

Contact the writer at fangaiqing@chinadaily.com.cn

(China Daily Global 11/01/2019 page15)