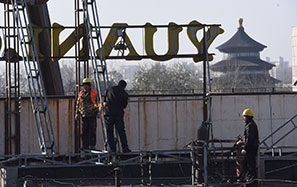

CREG tunneling to the top

Firm independently developed a high-tech machine that promises to be a paragon of nation's 'Created in China' effort

China Railway Engineering Equipment Group Co Ltd, one of the Chinese manufacturers that has developed its own independent shield tunneling machine, aims to secure a greater market share around the globe, according to the company's top executive.

"Our aim is to realize annual output of $1 billion by 2020 with $100 million profits, of which 30 percent will come from overseas markets," says CREG Chairman Li Jianbin.

According to Li, the independently manufactured shield tunneling machine is a good example of China's efforts to move from "Made in China" to "Created in China". A shield is a protective structure that serves in essence as a temporary support during tunneling.

CREG is a subsidiary of state-owned China Railway Group Ltd, focusing on the development and production of shield tunneling machines and tunnel boring machines. China used to rely completely on imports until 2008, when CREG developed its own shield tunneling machine independently after six years of research.

"The cost of machines fell from 60 million yuan ($9.17 million) to the current 40 million yuan per set," Li says. "Most importantly, we have broken the monopoly of foreign brands in China and starting from there, we plan to sell our products to the rest of the world."

This year, CREG will produce 60 to 80 sets of shield tunneling machines for the domestic market and also export to Israel, India, Singapore and other countries.

CREG takes up about 40 percent of the domestic market, according to Li. He says overseas expansion has only just begun.

"Our products are 20 to 30 percent cheaper than overseas brands because we sacrifice some of our profits to gain market share," Li says.

"Yet our biggest advantage is that China has extremely complicated and varied geological features. We have come across nearly every type of feature in our tunnel construction. Our machine designs can offer solutions to a wide range of needs for those overseas."

Li notes that the need for infrastructure construction remains, even though global economic growth is slowing.

His company plans to move its factories abroad so as to bring down transportation costs and as well as offer jobs locally.

According to a report on shield tunneling machines by Beijing-based Bosi Data Research Center, these devices have great advantages over traditional excavators in that they are safer, faster and more convenient. That is because they operate totally underground, without disturbing traffic above. Additionally they free staff from dangerous work.

"There is wide use of shield tunneling machines, mostly for metro projects, in water conservation, for expressways and for underground crossings," says Song Zhenhua from the Tunnel Machine Association of China.

"As a must-have for infrastructure construction, the market for the machine does not fluctuate significantly with economic growth," Song says.

Song says that China's technology for shield tunneling machine manufacturing is on par with the best in the world. Yet parts for the machine are still imported. China is still at the very beginning of catching up in high-end manufacturing.

Yet Song says it has made some major steps in terms of technological breakthroughs, and now marketing is particularly important in enhancing its brand recognition.

CREG has exported its products mostly to Asian countries, including Malaysia, Vietnam, India and Singapore.

"In terms of technology, we are on par with overseas brands. But international recognition of our brand is still very low," says Su Wenyang, deputy project director of the company's overseas department.

In one project in Singapore, for instance, it's the first time that rectangular pipe jacking has been used in the country to build tunnels. That's where rectangular pipes are jacked into place right behind a boring machine using hydraulic jacks.

Su says that employing such a novel method did not interrupt the traffic on the ground, with all work taking place below the surface. Moreover, it has effectively prevented collapsing or swelling in shallow earth excavation, Su adds.

yangziman@chinadaily.com.cn