Textile exporters take new approach

Apparel raw material providers in China have had to adapt by using new fabrics to combat labor costs at home

Zhao Miaoqi has witnessed many changes in China's textile industry during the past 40-plus years, and lately they have not been for the better.

"Over the decades, China's textile industry has changed dramatically," Zhao said. "It used to be a booming industry when I was young, but now it is old and declining. As more people (competitors) have flooded into the market, the (profit) margin has been shrinking."

Zhao has managed a fabric company in Ningbo, Zhejiang province since 1979, when China had just started reforms and was opening up. Her company specializes in products for overseas retail brands such as Zara, part of the Inditex Group in Spain, the world's largest apparel retailer, and Adidas AG, the German multinational corporation that designs and manufactures sportswear.

Last year, her company's orders in the United States fell by 30 percent. "I'm 75 years old and I'm coming all the way to visit the market to study the reasons behind the slump," she said.

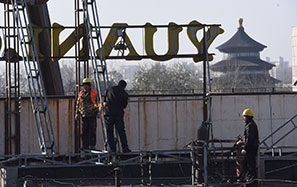

Zhao attended a three-day international textile and apparel sourcing show at the Jacob K. Javits Convention Center in New York on July 21-23, which attracted more than 600 Chinese companies - 30 percent more than last year.

Zhao's company, like others from China, is looking to establish new niche markets in the US.

China is a significant player in the global textiles markets. According to statistics from the World Trade Organization, the market was worth $766 billion in 2013. China holds a commanding market share of 37 percent, worth $284 billion. India is second, with a 4.7 percent share.

The low cost of business due to cheap labor has been the main reason why the textile industry in China has enjoyed extraordinary growth.

But today, China is no longer the cheapest producer. With the average wage of the 23 million textile workers in China reaching 4,000 yuan ($650) a month, garment-factory owners are starting to face financial pressure.

Zhao's grandson, Zhu Jing, manger of Ningbo Aoqi Technological Knitting Co, said the minimum wage is growing by 10 percent a year.

"By only offering the minimum wage, you can never recruit a skilled worker," he said. "As China has more rigid regulations on labor protection, employers must pay more for extra working hours."

In contrast, factories in emerging countries such as Vietnam and Cambodia have very low labor costs.

"Factories there offer as low of a salary as 300 yuan a month for textile workers, which is much lower than 4,000 to 5,000 yuan in China," Zhu said. "As they don't have rigid regulations, they force workers to work longer than required ... or hire some child laborers in order to cut cost."

Jack Plunkett, CEO of Plunkett Research, based in Houston, the US, and a provider of market research and industry information, said that in many parts of China, manufacturers have had increasing difficulty attracting and retaining workers. Wages have climbed dramatically, and as demand for employees has increased, workers have been calling for better conditions.

He said that the apparel and textile manufacturing industry has historically been one with few barriers to entry, requiring little capital investment needed and a lot of low-skilled labor and equipment. A few sewing machines and some dim electric lights were enough to start up a factory.

"When China's wages were extremely low, the nation had a clear advantage in this industry, particularly in light of its tendency to cluster factories near shipping ports and logistics centers so that goods could be sent to customers with minimal delay," Plunkett said.

"Today, however, wages are climbing very rapidly as China's urban workers have many options in terms of places and industries in which to work," he added. "Demand for workers is high, and they expect much higher pay than those in less-developed nations."

Labor costs are not the only challenge. Figures from the China National Textile and Apparel Council show that the momentum of China's textile industry has slowed significantly since 2011. From 2000 to 2010, average growth was 18.8 percent, but that dropped to 12 percent during the past four years.

The price of high-quality cotton in China is about 30 percent more than elsewhere, which caused fiber processing in China to drop by 26 percent last year, the council said.

China customs figures showed that the country's textile and apparel exports from January to April decreased 2.5 percent to $81.9 billion, compared with the same period in 2014. In April, the export figure plunged 16.4 percent.

BMI Research forecast that in 2015, India, Bangladesh and Vietnam will be the main beneficiaries of the decline in the Chinese textiles business. Those countries already have experienced a sharp increase in cotton and textile exports, due to favorable government policies, a young demographic profile and competitiveness due to a low-cost production base.

The good news for Chinese textile makers might be that the US market offers opportunity.

Zhang Qiyue, Chinese consul general in New York, said that China's textile and fabric industries have seen a rise in business with the US. From 2000 to 2014, bilateral textile and apparel commerce grew from $6.2 billion to $46 billion.

Exports from China to the US increased slightly from January to May. In April, exports of textiles and apparel to the US increased by 7.8 percent, according to China's National Bureau of Statistics.

As the euro is sliding to a nine-year low against the dollar and European economies are slowing down, the US market is taking on more significance for Chinese textile and apparel companies.

"More Chinese brands are on display this year. Most of them used to focus on the domestic market but are now focusing on the US market," Sun Ruizhe, vice-chairman of the China National Textile and Apparel Council, said. "They are supposed to offer more good options for the US business partners."

Jiangsu Sainty Fortune, a state-owned company, brought its winter collection to the New York trade show. "As Europe's economy is going down ... and the US economy is picking up, the market is more significant for us," Wu Hui, assistant general manager at Jiangsu, said. "The US and Canada now contribute more than half of our business."

Lei Shengzu, manager of China Textiles (Shenzhen) Co, said he is planning to set up a New York office by the end of 2015.

"It is supposed to better cater to the US market, which is expected to expand by 20 percent," Lei said. "Now orders from the US are still in small quantity, and we are striving to seek and develop a long-term partnership in the US market so as to get big orders."

The company also has invested more in research and development and set up a department to focus on innovation.

"The role of the department is growing increasingly important in the company," Lei said. "Previously, clients loved to bring some product samples of big brands and asked them to copy and sell at a lower price. We were very negative and passive, as we always had to wait for others' products."

Chinese companies are also starting to pay more attention to research and development. Instead of copying the big brands' designs, they are trying to develop new products to lift their own label awareness.

Although so far no Chinese company has succeeded in building an internationally renowned brand, industry professionals have started to work on creating a high-end label in the overseas market. "We have to upgrade services and offer new products more often to retain customers," Deng Zhijuan, an officer from Shanghai-based High Fashion Textile and Manufacturing Co, said.

The wide range of products and innovative material has increased raised in fabrics made in China, as designers are eager for inspiration from new designs.

"I have got many great ideas when walking past booths," said Vanessa Andrews, an independent designer. "The products are beautiful, and I've found some locket-like buttons, which would be suitable for my next collection."

Boris Litvinov, CEO of Active Line Corp, an apparel and fabrics business, said he has two suppliers from the mainland and four from Taiwan.

"For us, quality is more important than price," he said. "In recent years, the quality of Chinese products is getting much better.

"What China doesn't have now is the quality consistency from order to order, which is the key for Chinese suppliers to opening up the US market," he said.

lijing2009@chinadaily.com.cn

|

Two exhibitors display their company's textile products during the international textile and apparel sourcing show at the Jacob K. Javits Convention Center in New York.Wang Lei / Xinhua |