Company Special: SAP: Products will help make themselves in future factories

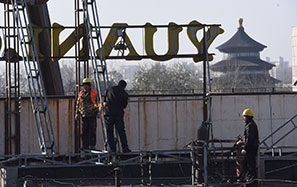

A factory of the future display by German software provider SAP was a highlight of this month's China International Industry Fair in Shanghai.

All objects in the display were able to communicate with one another - from machine-to-machine and machine-to-product - an approach that can achieve mass production as well as personalized products simultaneously. The technology can also predict errors in the production line to improve production efficiency.

"Industry 4.0, or the fourth industrial revolution, is characterized by the fusion of automation and digitalization," said Clas Neumann, senior vice-president, head of Global SAP Labs Network and Fast Growth Market Strategy Group. "Software is the glue that keeps the world of Industry 4.0 together. We are able to read what the devices say and communicate with robots what to do differently in the next stage and so on,"

SAP's vision seems just fit the demands of Chinese manufacturing companies seeking ways to improve production and management efficiencies amid increasing labor and raw materials costs. "Many manufactories in China are still in the transition phase from 'Industry 2.0' to 'Industry 3.0'," said Neumann. "Instead of doing only automation to transform to Industrial 3.0, it's a good opportunity to use the advanced technologies like big data technologies and predictive analytics to transform to smart manufacturing.

"In this case Industry 4.0 is deemed as the opportunity for those manufactories to have a leapfrogging growth".

China's central government announced plans to strengthen cooperation in Industry 4.0 with Germany on Oct 10. Former Vice-Premier Wu Bangguo, Minister of Information and Technology Miao Wei, Shanghai's Communist Party Chief Han Zheng and many other government officials visited SAP's booth at the China International Industrial Fair.

In the future, manufacturers need to offer and produce highly personalized products in order to remain competitive.

The manufacturing industry will evolve from mass production to mass personalization, said SAP. The results are more efficient, flexible production methods.

Products will know exactly what the next steps are, and organize the entire production process themselves, and communicate in the data cloud. This allows companies to involve their customers more closely in the production and service process, which also means manufacturers need to know more about their customers. In typical Industry 4.0 scenarios, manufacturers need to collect and analyze a lot of data, and use this information to develop and produce goods that match specific customer needs. As one of the world's leading information technology companies with cutting-edge data processing and analysis capabilities, SAP has the ability to solve the problem.

"Big data is not about amount of data. It is about who are the best companies to make sense of that data," said Neumann.

"When big data became a buzzword, we were fortunate to be the No 1 company in business processing and data analysis. We have innovated a database technology that allows access to data much faster," said Neumann.

The in-memory database technology introduced in 2011 was known as SAP HANA which can process massive amounts of data and deliver information at unprecedented speeds, up to 10,000 times faster than before.

It was believed by SAP that to drive the business, the rearview mirror is tiny compared to the windshield looking forward.

In the future, companies will start to build forward-looking decisions into their operating models through the adoption of SAP HANA and SAP Analytics solutions that unleash the power of collective insight.

According to Neumann, SAP HANA is a revolutionary in-memory platform that will help to process massive amounts of data in a manner that not only enables customers to make decisions for today, but also provide a powerful predictive engine.

"It dramatically simplifies and streamlines complex and expensive IT architecture," said Neumann.

"As an open, adaptable and scalable platform, SAP HANA enables enterprises to create previously unimaginable applications on top of it and to rethink and envision new ways to run their businesses."

In 2011, drinking water company Nongfu Spring was the first to implement the SAP HANA system in the Asia-Pacific region.

According to Nongfu Spring, it normally took 24 hours to process settlement reports .

Sometimes it was not possible to generate a report timely because simply the system cannot process so much data.

The implantation of SAP HANA allows Nongfu to process reports in only 46 seconds.

China market

For SAP, China has the potential to become the biggest market in new software sales by 2020, boosted by robust cloud and database demand. SAP has established research and development teams around China to better hear and meet client demands.

Its China R&D lab headquartered in Shanghai has become its third largest globally outside Germany.

Eyeing businesses opportunities in China, SAP is working closely with research institutions, government authorities and businesses to build the ecosystem needed for realizing Industry 4.0.