Swiss engineering group to spend $300 million on production plant

The Swiss engineering group ABB says it is looking to double its presence in China to 200 cities at present in the next three years.

|

Ulrich Spiesshofer, chief executive officer of ABB Group, says the company aims to have 20,000 people working for it in China soon and pursue growth drivers such as energy efficient technologies and infrastructure to increase profits.

At the same time, the company will make additional investment to boost its manufacturing capabilities in China. ABB will spend $300 million over the next five years to set up a production hub for power and low voltage products in the coastal city of Xiamen in Fujian province.

Since 1992, Xianmen has become one of ABB's largest global business hubs, covering the full value chain of research and development, manufacturing, engineering, sales and services in the low-voltage products and power businesses, Spiesshofer says.

ABB China's shared services, supply chain management and corporate functions, employing nearly 4,000 people, are also located in the city.

Spiesshofer says ABB will continue to seize the opportunities that arise from China's urbanization and industrial upgrading. China's new focus is on quality urban development, as well as green, low-carbon and sustainable growth such as building high-efficiency grid networks and promoting the use of industrial robots, government sources say.

"If we look at the speed of urban development in China, and the way the regulatory environment and infrastructure development comes together, it is a remarkable and unique growth opportunity," Spiesshofer says.

"The planning and perseverance that governments show in building prosperous cities is something that is worth emulating," the CEO says.

With the population in many of China's second- and third-tier cities much larger than those of big cities elsewhere in the world, building ultra-high voltage power transmission networks and new energy vehicle projects, as well as providing more industrial robots, is useful to keep up the pace of urbanization and make the most of the country's manufacturing structure.

Thanks to China's industrial upgrading boom, ABB China's revenue grew 7.7 percent to $5.6 billion last year. The company's cumulative investment in China reached $1.8 billion last year, with $136 million being the actual investment in 2013.

ABB employs 19,000 people in 37 local companies and has a sales and service network covering 109 cities. The lion's share of the company's revenue in China comes from local manufacturing.

Many Chinese cities have drawn up plans for economic and industrial transformation, along with solutions to tackle problems caused by rising labor costs, an aging society and low work efficiency, so companies such as ABB can expect continued business growth in China, analysts say.

"Even though China's GDP growth in 2013 was lower than in previous years, the investment on green-energy and high-end products will add to prosperity and benefit the economy and the environment in the long term," says Sun Fuquan, a researcher at the Chinese Academy of Science and Technology for Development in Beijing.

|

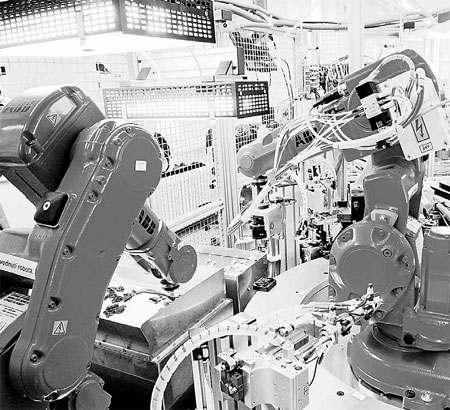

| Robots made by ABB Group are helping China keep up its rapid pace of urbanization. Photos provided to China Daily |

Gu Chunyuan, senior vice-president of ABB Group, says China's rapid growth and its urbanization plans have prompted labor-intensive industries to find new ways to cope with increased demand.

"Most of the companies face problems in finding talent and retaining it as attrition rates are increasing in sectors such as computers, communication and consumer electronics product manufacturing," Gu says.

"By combining customer demand, we have gradually shifted our focus on industrial robot research and development in China from large robots oriented for automation to small robots for computer, communication and consumer electronics products' industrial upgrading."

ABB introduced a new type of robot fully developed in China, the IRB 120, last year. It is the company's fastest and most accurate six-axis robot. It is small and weighs just 25 kg, so it can be placed in any location or even hung upside down or mounted on the wall.

Gu says the robot has obvious advantages in limited spaces, especially in small work piece processing, material movement and assembly. This high-end product has become the preferred product for industrial upgrading of smaller-sized electronic products in China and is selling well elsewhere, he says.

Robots can boost productivity, particularly in dirty, dangerous and unsafe work environments without any added labor costs, leaving the human workforce to focus on other work.

The industrial robot market is seeing an explosive growth in China, Hu says. Demand for industrial robots in China is expected to reach 35,000 by 2015, accounting for 16.9 percent of the total global sales, making China the largest robot market in the world, says statistics published by the Frankfurt-based International Federation of Robotics.

Because of the wide application of industrial robots and its inalienable role in smart manufacturing and production, companies such as ABB are now focusing on using them across the whole value chain in China, including research and development, production, sales, engineering and services.

Last year, ABB provided robotic products and automotive manufacturing solutions to auto major BMW Brilliance Automotive Ltd's Tiexi production base in Shenyang. On the BMW assembly line, ABB robots are mainly engaged in handling, gluing and welding work. ABB has also provided robotic automation solutions to Volvo Car Group's Chengdu automobile production base, becoming the first robot supplier to provide the water-based adhesive system solution in China.

"This solution reduces noise and vibration throughout the whole car while it is moving, and creates a quiet and comfortable driving environment for owners. It also greatly reduces the amount of volatile and organic compounds needed during manufacturing, thereby minimizing environmental pollution and damage to human health by improving the air quality in the car," says Jiang Haibo, vice-president and head of service, ABB North Asia and China.

ABB China's service business continued to maintain its strong growth last year. The company added six service centers in China, including Hangzhou, Chongqing, Jinan, Xi'an, Wuhan and Shenyang, bringing the total number of service centers to nine.

It also has more than 90 professional service stations and more than 200 authorized service providers throughout the country.

Contact the writers at zhongnan@chinadaily.com.cn and lifangfang@chinadaily.com.cn