|

|

|

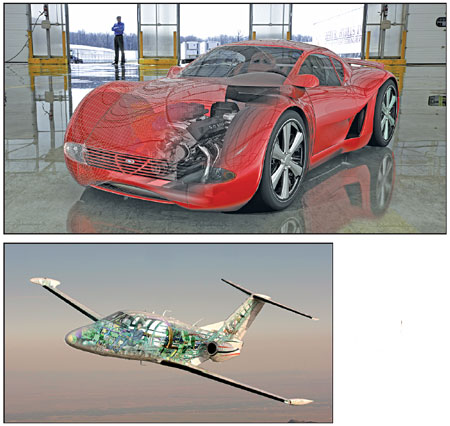

Siemens PLM software is widely used to design and simulate the performance of airplane and car components. Pretest simulation on digital platforms can save time and money compared with traditional physical testing. [Photo/Provided to China Daily] |

'Bright future' for Siemens PLM software in China as firms seek an edge, says CEO

Though winds of change are sweeping across the manufacturing landscape with tremendous speed, countries like China can still retain their winning edge by using innovative industrial software that can integrate the product development and production processes, a top industry official said.

Much like cloud computing that is transforming the information technology business, it is "Industry 4.0" - a concept that promotes the digitalization of the manufacturing industry - that is now being hailed as the way forward for manufacturing companies.

German industrial giant Siemens AG has been the most notable supporter and proponent of the concept, which is essentially a collective of smart factories, intelligent machines and networked processes that provide a direct and real-time interface between the virtual and physical worlds.

Chuck Grindstaff, chief executive officer of Siemens PLM Software, believes that China would be the biggest market and largest buyer of the new solutions that are spearheading the so-called next industrial revolution. "China's competitive advantage was low-cost labor initially. But in the long run, its sustainable advantages would be innovation and quality," said Grindstaff.

His remarks come at a time when policymakers are looking for ways to make China's growth innovation-oriented, rather than driven by low-cost labor. Grindstaff said that the Industry 4.0 concept would help Chinese manufacturers hone their competitive edge globally and move up the quality, innovation ladder.

"We have a team of people who are well aware of the new concepts and processes, and our products are well-suited for the Chinese marketplace," said Grindstaff, whose company has been rated as the market leader in China's product lifecycle management sector for 13 years in a row, according to consultancy and research firm, CIMdata Inc.

The Texas-based Siemens PLM develops software that can manage the entire lifecycle of a product from designing to manufacturing, to deployment and even disposal. It is seen as a key enabler for countries like China that are on the cusp of an industrial transformation, experts said.

Policymakers are already working on an industry blueprint known as "China manufacturing 2025" that aims to make China a manufacturing leader by 2025 and zoom past Germany and Japan by 2035.

A cutting-edge project that showcases the advantages of PLM software is Siemens' digital factory in Chengdu in Sichuan province.

The factory, Siemens' only digital workshop outside of Germany, is a highly automated unit where production materials are sorted and delivered to the exact production line at the exact time without workers lifting their fingers. The machines are also smart enough to "talk" to each other and make their own decisions by using well-designed connectivity machines.

|

|

| Top 10 German enterprises operating in China | Siemens, BAIC join hands to boost new energy cars' market |