City builds modern industry system for economic surge

|

|

A high-speed train made in Chengdu. The city has attracted a number of advanced manufacturers, who are expected to help it with its goal of becoming a national central city. |

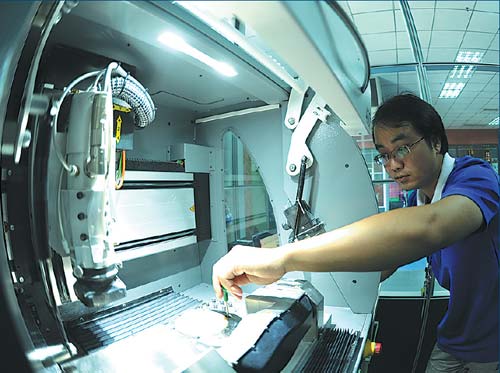

The first Peugeot 4008 car produced by the Chengdu plant of Dongfeng Peugeot Citroen Automobile, a joint venture of French carmaker PSA Peugeot Citroen and Chinese automaker Dongfeng Motor Corp, rolled off the production line on Sept 7.

The Chengdu facility is DPCA’s fourth manufacturing plant in China. It mainly produces vehicles for both the Peugeot and Citroen brands, as well as Dongfeng’s Fengshen brand, with a focus on highend sport utility vehicles and multipurpose vehicles.

With a total investment of 12.3 billion yuan ($1.9 billion), the plant has a planned annual production capacity of 360,000 automobiles.

|

|

A technician tests equipment at Dongfeng Peugeot Citroen Automobile’s Chengdu plant.[Photo provided to China Daily] |

“The commercial operation of the Chengdu plant marks another solid step for the development of DPCA and Dongfeng Motor in western China,” he said, adding that Chengdu is the gateway for the company to implement its westward-reaching strategy.

Carlos Tavares, chief executive officer of PSA Peugeot Citroen, said the Chengdu plant adopts the world’s leading technologies in the auto industry.

The all-new Peugeot 4008 will help DPCA to explore the high-end SUV market in China.

DPCA will accelerate its pace of development in western China, he said.

Chengdu has already established itself as a major auto manufacturing base in western China, represented by its complete auto industrial chain.

The State-level Chengdu Economic and Technological Development Zone, located in the eastern part of the city, has gathered automakers including DPCA, FAW-Volkswagen, Zhejiang Geely Holding Group and Volvo, as well as many car component suppliers.

The city is expected to produce 1.1 million units of vehicles this year. The auto industry is expected to generate a total output value of 200 billion yuan.

Chengdu plans to become a world-class auto base by 2025, with an annual output capacity of three million cars, according to the Made in Chengdu 2025 program.

|

|

A worker runs a machine at the CREC Industrial Park operated by China Railway Eryuan Engineering Group. [Photo provided to China Daily] |

As the sole supplier of rudders for the Boeing 787 Dreamliners, Chengdu Aircraft Industrial (Group) has delivered 535 of the planes’ rudders to Boeing.

It also provides other components such as boarding gates, ailerons and spoilers to international aircraft manufacturers including Boeing and Airbus.

“We are proud to work with AVIC companies including Chengdu Aircraft Industrial (Group), to meet Boeing’s requirements for high quality, affordability and on-time delivery while expanding China’s aviation manufacturing capabilities,” said Ian Chang, vice-president of China Operations and Business Development at Boeing Commercial Airplanes.

An aerospace industrial park started construction in the city’s Xindu district in early October.

With a planned total area of 9 square kilometers, the park will focus on the manufacturing of aircraft engines and engine components, as well as other related industries. It is expected to attract 60 companies by 2025, generating main business income of 30 billion yuan.

One of China’s major aerospace bases, Chengdu has rich experience in the R&D of national key aircrafts including the F-7, FC-1/JF-17, F-10 and some unmanned aerial vehicles.

China’s first domestically designed large passenger jetliner, the C919, is preparing for its maiden fl ight and is equipped with many components and parts made in Chengdu, including its nose, inflight entertainment system and communication and navigation systems.

AVIC Chengdu Engine (Group) is one of China’s major research and manufacturing bases for aircraft engines.

The company has strategic cooperation with leading aircraft engine makers including GE, Pratt Whitney Group and Rolls-Royce Holdings Plc.

According to the city’s plan, it will be a leading aerospace industrial base with a complete industrial chain and annual output value of 100 billion yuan by 2020.