Putting theory into action paying dividends for textile industry

Researcher Yu Guangping has made great efforts to transform research achievements into action at traditional companies, refreshing their practices and creating higher revenue for them, Science and Technology Daily reported.

In 2009, Yu completed his doctorate at the Shenyang Institute of Automation under the Chinese Academy of Sciences. He decided to work in the institute and research intelligent and green manufacturing in the textile dyeing industry.

At that time, Yu had achieved some scientific results and hoped to industrialize them.

It is not an easy job to commercialize research results in China. Some 90 percent of scientific research results have yet to be commercialized in an industrial setting, the Beijing-based newspaper reported.

To accelerate the use of technological achievements in the industry, the Shenyang Institute of Automation and the Guangzhou city government established a Guangzhou branch of the institute in Guangdong province in 2011.

Yu said that it was an excellent opportunity for research achievements to take root in the Pearl River Delta region, which boasts the most developed manufacturing industry in China. So he applied for a position at the Guangzhou branch.

After arriving in Guangzhou, Yu conducted research on local companies. He found that there were many printing, dyeing and electronic companies in the city, which generated a large quantity of sewage and harmful waste.

He decided to focus on industrial sewage treatment and aimed to provide intelligent and green manufacturing solutions for printing and dyeing companies.

Yu started his survey in Guangzhou (Panyu) Pacific Textiles in 2012. He changed the reagent added to wastewater treatment - from liquid alkali to quicklime. He also adjusted the dosage according to the dynamic situation of water quality after two months of experiments.

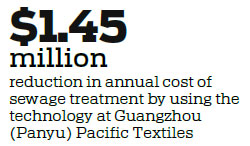

"It will be able to reduce nearly 10 million yuan ($1.45 million) in annual cost of sewage treatment by optimizing the chemical agent formulation," Yu told the newspaper.

"Big data also helps to analyze the causes of sewage effluent fluctuation and give diagnostic conclusions and suggestions to deal with them," he added.

The company has adopted the automatic operation method provided by Yu in the dyeing process, which accurately controls the process parameters and conveys the dye auxiliary agent. The success rate of the new dyeing method is higher than 90 percent, well above the industrial average.

This helps to increase output value, reduce workers' labor and improve the production environment, according to Yu.

Last year, the workforce of Pacific Textiles declined from more than 7,500 to 4,000. But the company's per capita output value surpassed 1.1 million yuan. The average output value of this traditional processing manufacturing company is equivalent to a high-tech enterprise, according to Science and Technology Daily.

In addition to the textile company, the research achievements in intelligent manufacturing developed by Yu and his team have also been used by scores of Chinese companies and exported to countries and regions involved in the Belt and Road Initiative.

caoyingying@chinadaily.com.cn

(China Daily 07/25/2019 page17)