New generation stars plug-in hybrid models

BMW further solids the leading position with highly electrified hybrid power train, intelligent eDrive component-sharing-system

The BMW Group is well repared to follow up its innovative and revolutionary BMW i models with plug-in hybrid versions of its corebrand models.

Before the world premiere of BMW X5 PHEV in Shanghai, the group presented a BMW 3 Series plug-in hybrid prototype and a new generation of hybrid vehicle concepts incorporating technology already used in BMW i models, last November in Europe.

In the long term, the group plans to offer plug-in hybrid versions of all its core-brand models.

According to BMW, all of its models will benefit from BMW i.

The fundamental technology involved in battery cells, electric motors and the power electronics will be used in the upcoming plug-in hybrid models.

When it comes to the electrification of the drivetrain, the company will deliberately developing a wide-ranging expertise in order to offer customers worldwide the ideal solution.

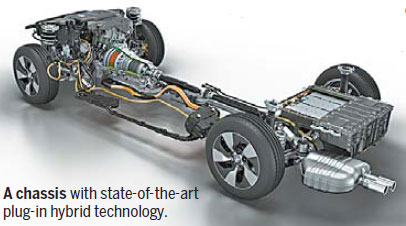

The plug-in hybrid models presented in Miramas are equipped with a highly efficient internal combustion engine and an electric motor powered by an externally rechargeable high-voltage battery.

Shorter-distance urban trips or commutes can be completed on electric power only. On longer journeys, the vehicle will usually operate in "combined mode", with both systems working together.

The BMW 3 Series plug-in hybrid prototype combines a four-cylinder petrol engine with an electric motor.

The internal combustion engine is based on the TwinPower Turbo four-cylinder petrol engine that has already twice been voted "International engine of the year" by authoritative media.

The electric motor and power electronics are directly based on the BMW eDrive technology already used in the BMW i3 and BMW i8 models.

The prototype's lithium-ion battery, including the battery management system and the high-efficiency direct cooling system, are likewise based on BMW i experience and know-how.

The plug-in hybrid technology is so flexible that it can be integrated into a wide variety of vehicle concepts, therefore making it possible to deploy it rapidly across the BMW model range. The route to sustainable mobility in the future will be multitrack.

The already efficient combustion engines will become even more economical.

All-electric vehicles such as the BMW i3 are tailored to urban mobility requirements while plug-in hybrids are more appropriate for longer-distance journeys.

Beyond this, in the long term electric mobility in conjunction with hydrogen fuel cell technology could also be a viable option.

The focus of the company's "EfficientDynamics" strategy is the electrification of the power train.

This is an area in which the company will continue to expand in the coming years.

The plug-in technology will be one key lever to bring high performance vehicles well below 100g/km CO2, while retaining the driving pleasure and driving dynamics of a BMW.

The company will also continue to develop fully electric mobility. Hydrogen fuel cells will remain a key issue when it comes to drivetrain development, especially relating to sustainable production.

Key eDrive technologies

All the important eDrive technologies and components are developed in-house of BMW, and from 2015 they will all be built at the BMW plant inDingolfing.

This program is set to create more than 200 new jobs around electro-mobility at the BMW plant in Dingolfing. Tens of millions of euros will be invested at the plant over the next five years.

"Our accumulated expertise guarantees us a competitive edge," said Harald Krger, member of the board of management of BMW AG, Production. "This can be seen not only in the performance data of the BMW electric motors but also in our highly efficient production process."

As the group expects to be building a wide range of electric drive components in the future, production will be organized around an intelligent eDrive component-sharing system.

This means the same production line will be able to build high-voltage battery modules not just for the BMW i8 but also for the future BMW X5 eDrive.

In the case of complete battery packs, the new production lines will also be designed for a flexible production mix, meaning it will be possible to build battery packs for a number of different models on the same lines.

Highly electrified hybrids

With the ongoing development and refinement of hybrid drive systems under the "EfficientDynamics" strategy, the aim is to maximize the amount of time the vehicles are able to spend in electric mode.

To ensure that this increased electric operation goes hand in hand with typical BMW dynamic performance, everyday practicality and maximum long-distance capability, BMW's future hybrids will be "highly electrified".

Highlights of this future Power eDrive technology will include much more powerful electric motors and batteries with twice the capacity of present versions.

The drive systems used in these future hybrid systems will offer combined outputs in excess of 500 kW.

Also, the capacity of the lithium-ion batteries - up to 20 kilowatt hours - will far surpass the current hybrid systems.

Coupled with an increased all-electric driving range of up to 100 kilometers, this will make it possible to operate in emission-free pure-electric mode on most day-to-day trips.

lifusheng@chinadaily.com.cn

(China Daily 04/20/2015 page4)