Power becomes supercritical

|

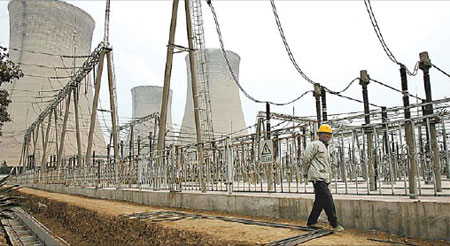

A worker walks past power cables and cooling towers outside a Huadian Power International Corporation coal power plant in Zoucheng in East China's Shandong Province. Danfung Dennis/Bloomberg News |

On the shore of the East China Sea is the blocky structure of Yuhuan power station, belonging to China Huaneng Group, the nation's largest power manufacturer. Located in Taizhou, Zhejiang Province, it is one of Huaneng's latest projects.

Around 900 kilometers to the north, in Zoucheng, Shandong Province, there is another plant of similar size run by China Huadian Corporation, another leading power manufacturer in the nation.

Two milestones marked the beginning of widespread use of supercritical and ultra-supercritical technologies in power plants.

More than 100 such power generation units are now being built by Chinese power generators and international manufacturers to replace in three to five years the inefficient, small thermal power stations built during the hectic business expansion of the 1980s and '90s.

Yuhuan's phase I has two 1,000 megawatt (MW) units, each with a capacity ranking the largest in China. After the first two units went into commercial operation at the end of last year, Huaneng now has a phase II plan for Yuhuan to build another two 1,000 MW units in 2008.

The Yuhuan power plant was started in 2004 with a total budget of about 9.6 billion yuan.

The ultra-supercritical technology as well as the supercritical technology are the most advanced thermal power technologies used in the world today. With either technology, a power generating unit operates under a mix of temperatures and pressures above the critical point, at which the boundary of water's liquid state and a vapor state disappears. By eliminating the transition of water into steam, the power units markedly increase fuel efficiency.

According to the London-based World Coal Institute, power plants that use supercritical generating units have an energy efficiency that can reach up to 46 percent. For ultra-supercritical plants, the efficiency can be as high as 50 percent.

Energy efficiency of conventional power plants currently in use in China is 30 percent to 40 percent.

Developed since the '50s

The US was the first country to develop supercritical technologies, when in 1957 it began operation of such power generating facilities. In the 1980s, developed countries such the US and Germany continued the development of ultra-supercritical technologies.

There are more than 240 supercritical units worldwide, with China operating 22. There are reportedly only 24 ultra-supercritical units in use worldwide, mainly in Germany, Japan and the US, according to the World Coal Institute.

"Ultra-supercritical and supercritical technologies are expected to become more prevalent in China's thermal power plants because of their higher energy efficiency over conventional power plants, and their lower emission of pollutants," says Han Xiaoping, a veteran energy analyst with China5e.com, one of the leading energy websites in China.

In an initiative led by the central government, China has undertaken a campaign to close down its small and often energy inefficient and highly polluting power plants with outdated technologies.

The National Development and Reform Commission (NDRC), the nation's top economic planning body, requires that by 2010, China will close down all its coal-fired power plants that have a combined capacity of 50,000 MW.

At the same time, China will also close all small oil-fired power plants with capacity between 7,000 MW and 10,000 MW, the NDRC stipulates.

The plants to be shut down include conventional units with capacities under 100 MW that have been in operation for over 20 years.

The nation will encourage the use of power generating units with capacities of or over 600 MW in its new power plants, it will also encourage the use of supercritical and ultra-supercritical technologies in new plants.

Low environmental load

"The advanced technologies in power generation will help China to use coal with high efficiency and low environmental load, which can promote the sustainable supply and use of the energy," says Han.

According to statistics from Huaneng, after half a year of operation, its ultra-supercritical units consume 283.2 grams of coal to produce one kilowatt-hour of electricity, compared with some smaller generators that use around 1,000 grams per kilowatt-hour.

Now that China has developed the capacity to produce supercritical and ultra-supercritical power generating units, the nation's three power equipment giants, Shanghai Electric, based in Shanghai, Harbin Power Equipment Corp, based in Heilongjiang Province, and Dongfang Electric Corp, based in Sichuan Province, have all begun to make the equipment.

The units at the Huaneng Yuhuan power plant were supplied by Harbin Power Equipment and Shanghai Electric. The ultra-supercritical power plant completed by China Huadian Corp used equipment made by Dongfang Electric.

"Now the three companies have received orders for around 100 supercritical power generating units," says an analyst who declined to be named. "For ultra-supercritical units, they have received orders for around 30 units."

In addition to domestic producers, foreign companies are also eyeing the market. Last year, French industrial giant Alstom and its partner Beijing Heavy Electric Machinery Works opened a new joint venture, Alstom Beizhong Power (Beijing) Co Ltd, which is the first manufacturer of 600 MW and above sub-critical, supercritical and ultra-supercritical steam turbine and generator units.

The joint venture, in which Alstom holds 60 percent, is the largest French-invested manufacturing project in Beijing.

(China Daily 09/07/2007 page44)