From sunset to sunrise

Reindustrialization has reinvigorated Hong Kong's once-pulsating, money-spinning manufacturing business, helping the trade to turn the tide after decades in the doldrums. Liu Yifan reports from Hong Kong.

When Hong Kong's manufacturing industry - a key pillar of the city's economic success in the 1960s and '70s - stopped in its tracks and went into a steep dive following its golden decades, many thought it was the end of the once-throbbing sector.

The industry's decline was fueled by its shrinking share of the local economy and underutilization of industrial premises after manufacturers started a mass exodus, relocating their operations to low-cost destinations on the Chinese mainland and other parts of the continent, notably Southeast Asia.

A new lease of life for the sunset trade emerged when an array of Hong Kong producers began integrating innovative technologies, such as sensors and machine vision, into their traditional production lines in recent years, reviving hopes of a comeback.

Hop Hing Oil Group - Hong Kong's only cooking-oil company that operates an oil-refining plant - launched its smart production line last year to boost output and deal with the problem of a dearth of manpower. It did well, helping the company to double its production capacity, while reducing manpower, production time and human error.

It also offered a glimpse into the city's ramped-up efforts to lift the innovation-driven economy by restoring its manufacturing allure.

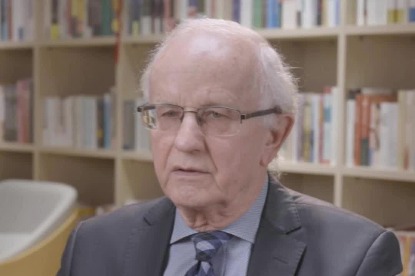

Eric Fong Wai-ching, chair professor in sociology at the University of Hong Kong, reminisces that Hong Kong's manufacturing activities had undergone expansion at a breakneck pace in the 1950s and '60s. The influx of manufacturers and capital from the mainland during the civil war in the late 1940s offered essential expertise and resources for industrial progress.

Industries like textiles, toys and electronics production became the cornerstone of the city's economy in the 1970s, with manufacturers accounting for more than 30 percent of the GDP.

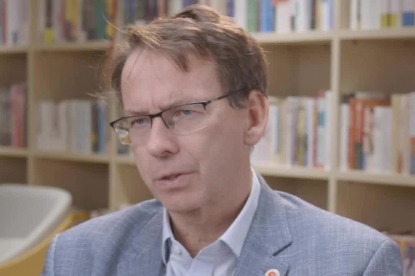

Alfred Lau Chun-to, founder and CEO of local chip design startup PDL Technology, says Hong Kong was seen as a hub for world-renowned electronics enterprises setting up regional offices in the 1980s, while engineering was one of the most sought-after majors among the younger generation, along with medical science.

Motorola forayed into Hong Kong in 1982 when the US electronics giant inaugurated a multimillion-dollar facility in Kwai Fong. An advanced integrated circuit design center and a fully automated assembly center added impetus to the company's operations in 1986 and 1988 respectively, followed by the 30,286-square-meter Silicon Harbour Centre, which opened in Tai Po in 1990. The facility housed Motorola's Asia-Pacific headquarters, which included design, computational and manufacturing facilities for advanced semiconductors and microprocessors.

However, manufacturing came under pressure after Hong Kong repositioned itself as a service-oriented economy. This trend coincided with surging labor and land costs, which also led to the closure of Motorola's Hong Kong factories in the 2000s. Manufacturers' share of the economy plummeted to less than 1 percent in 2019. In stark contrast, the sector's GDP share in the other three Asian "tiger economies" - Taiwan, South Korea and Singapore - stood at 30 percent, 25 percent and 20 percent respectively, according to the HKU's Business School.

Good progress

Reindustrialization advocates issued a clarion call after the city recorded negative growth three times from 2019 to 2022, except in 2021.

It heralded the start of an ambitious reindustrialization effort. In late 2022, the Hong Kong Special Administrative Region government unveiled its innovation and technology development blueprint, outlining 16 targets and 42 initiatives for the next five to 10 years to reboot manufacturing strength, woo the brightest minds, and deepen inno-tech cooperation with the mainland.

The goal is for the Asian financial hub to reindustrialize itself, develop a diversified economy, create quality jobs, improve residents' quality of life, and serve the nation's needs for technological self-reliance. The blueprint calls for the SAR government to expand its manufacturing sphere - from below 1 percent of the city's then GDP to 1.5 percent in five years, and to around 5 percent in a decade.

Secretary for Innovation, Technology and Industry Sun Dong said the GDP target for the manufacturing trade to produce HK$400 billion ($51.28 billion) in economic output in the next 10 years wasn't a "conservative goal".

In a sign that reindustrialization is gaining pace, the Innovation and Technology Commission launched a HK$10 billion funding program in September for firms in strategic sectors like health technology and artificial intelligence to set up new smart production facilities.

The program is part of Chief Executive John Lee Ka-chiu's bid to support the innovation and technology field, as outlined in his Policy Address last year.

Under the New Industrialization Acceleration Scheme, each project must be worth at least HK$300 million. Participating companies are required to contribute a minimum of HK$200 million, with the government funding ceiling set at a maximum of one-third of an approved project's total cost, or HK$200 million, whichever is less. Each company can have two projects endorsed at most, and will get a total of up to HK$200 million.

A new trail

Alvis Kong, a partner of strategy and economic advisory at Deloitte China, sees the SAR government as having actively enforced policies and measures in finance, manufacturing, research, and supply chain management to stimulate industrial innovation and enhance productivity in recent years through a multipronged approach to support the further development of the manufacturing ecosystem.

He says a new wave of technological innovation will provide opportunities for the transformation and upgrading of the manufacturing industry in light of a resurgence in industrialization and the country's push for new quality productive forces - a term that sets old growth models apart from innovative and eco-friendly sectors.

The administration's reindustrialization push is nothing like the former labor-intensive path. Its centerpiece is to streamline production processes for nurturing high-value-added sectors and industry supply chains by virtue of Hong Kong's reputation in research and development, design and intellectual property protection, as well as innovative technologies, such as artificial intelligence and new materials.

Guo Wanda, executive vice-president of the China Development Institute, told a recent seminar that the focus of Hong Kong's new industrialization shouldn't be "why", but the specifics of "how". This includes the need to optimize the industrial structure and demand for regional collaboration.

To give teeth to the plan, he stressed that to leverage Hong Kong's resources and endowments for new industrialization, it should center on key sectors, such as microelectronics, artificial intelligence, biotechnology, new energy vehicles and new materials.

Edmond Lai Shiao-bun, chief digital officer of the Hong Kong Productivity Council - a statutory body that offers technological transformation solutions - wants the manufacturing business to embrace a new normal of customized production and sustainable development.

A recent survey of 288 manufacturers conducted by the HKPC showed that nearly seven out of 10 respondents agreed that the emerging trend is to create "lots of variety in fewer quantities", necessitating swift adaptation to meet customer needs.

However, the practical adoption of innovative technology remains limited, while businesses acknowledge the significance of personalized small-scale manufacturing. According to the poll, only 19 percent of the manufacturers had implemented "smartification solutions", while 53 percent saw a lack of strategies in this area.

"As customization disrupts conventional production methods, Hong Kong can seize this trend as a chance to innovate new manufacturing approaches," says Lai. Local garment producers are notable examples. With the creation of a digital knitted garment smart production line suitable for small-batch and diverse-style production, the HKPC notes that traditional manufacturers have increased their capacity by 35 percent and cut costs by 40 percent. Such a production method could facilitate tasks ranging from product design, digital sample simulations, engineering parameters, and programming to smart production.

At the same time, sustainability is gaining ground, with 67 percent of the enterprises surveyed getting current or anticipated customer demand for the integration of eco-friendly sustainability practices into their manufacturing operations.

Lai says the growing international need for eco-friendly manufacturing will emerge as a fresh catalyst for growth in Hong Kong's service sector as green manufacturing presents immense business potential given its wide range of domains and technologies, encompassing energy management, carbon footprint reduction, sustainable certifications and training, and green finance. "The nation's new quality productive forces offer us a chance for evolution and enhancement, with technological innovation poised to drive our progress."

Through reform and upgrading, he says technological innovation will be the focal point for enriching value, while the intrinsic strengths of Hong Kong's manufacturing sector will underpin the progression to new industrialization.

Contact the writer at evanliu@chinadailyhk.com

- State firms build greener supply chains

- China launches commercial trial of satellite Internet of Things services

- Shanghai team builds 7-min dementia detector

- Guizhou's new rail line to aid tourism

- Platforms face stringent new privacy rules

- Innovation raises golden fields from former barren salt flats