Job with strings attached

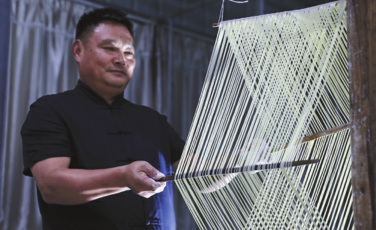

Liu Laiwang mass produces hollow noodles, contributing to rural vitalization, Yang Feiyue reports.

Huangchuan county, in Central China's Henan province, is covered with rice paddies, but the residents' favorite food is not made of rice. Rather, it is the Huangchuan hollow gongmian (tribute noodle), a distinctive dish that dates back to the Tang Dynasty (618-907).

The noodles are sweet and thin, cook quickly, do not get sticky in soup, and are famous for their hollow, tubelike shape.

"You can stick one in the water, blow into it, and bubbles come out," says Liu Laiwang, who has made a career out of making them, founding Wangxin Hollow Noodle Co in 2006.

Hollow gongmian are intimately connected with the culinary tastes of past imperial dynasties, as evidenced by the character gong in the name, which translates to "tribute".

Local chronicles compiled during the reign of Emperor Guangxu (1871-1908) of the Qing Dynasty (1644-1911) record that the county had been producing hollow tribute noodles for centuries by that point, and that their popularity had spread far and wide.

The noodle even made its way onto the tables of the banquet celebrating the 100th day of the Tang Empress Wu Zetian's rule, hard-won as she was the only female ruler in China's history.

It became a customary tribute offering to the royal family during the Song Dynasty (960-1279), later spreading and thriving among wider society.

In late February, the hollow noodle was featured in a large intangible cultural heritage exhibition held by Henan's provincial culture and tourism department and the Zhoukou municipal government. Participants got to see how the noodle is fashioned by craftsmen and taste it on site.

Liang Fengming, a noodle maker who works with Liu's company, explains to exhibition-goers their process: "To put it simply, we let the exterior of the noodle dry first, and then the wet internal part will stick to the dry outer part."

This was an oversimplification for laymen, hiding the copious, precise and exacting work behind the noodles' production.

Ancient craft updated

"The process usually starts in the evening," Liu says.

First, wheat flour is mixed with salt water before being kneaded repeatedly to increase elasticity.

"Working on a piece of dough that is about 50 kilograms requires more than two hours of uninterrupted kneading."

Oil is then added, which creates small air pockets in the dough, whereas the salt not only adds flavor but "increases the elasticity of the gluten in the dough, making it easier to hang and stretch, which also contributes to the formation of air pockets", Liu says.

After the dough is finished, it is left to ferment, then rolled and shaped and left overnight.

The next morning, the noodles are twisted around chopsticks and placed in a dedicated trough for further fermentation.

When the noodles are at their optimal resilience, they are "exposed to sunlight and air for two hours until they are about 90 percent dry."

After this long process, the finished noodles are silk thin and carry a silver luster, featuring spiral hollows as small as a needlepoint.

"No matter if it is weddings, birthdays, or other festive occasions, Huangchuan hollow noodles are indispensable," Liu says.

Sales have always peaked during Spring Festival, especially when locals leave home to return to work. "They always bring some with them. A bowl of the noodles can bring comfort, reminding them of their hometown and loved ones," he says.

Liu, now in his 50s, was exposed to the hollow noodle in his childhood, when his father and many other local elders produced it for a living.

In 1996, Liu joined a local wheat processing enterprise and got to learn from experienced masters.

In 2006, he decided to start his own noodle business, and to go big with his plans.

As producing the historical noodle relied heavily on transmission of complex skills from generation to generation, most producers operated out of small family-based workshops, which could only produce 80-90 kilograms of products per day.

Moreover, due to weather conditions, production was often halted for five months each year, resulting in low productivity and a significant market gap.

Liu decided to mass produce the noodle by recruiting, training and employing local workers who had little experience.

"I first show them the whole production process, and then have them work with experienced noodle workers," Liu says.

It usually takes about a week for a novice to get the fundamentals before they can start to hone their skills to complete the trickier parts of the process, such as hanging, which requires stretching out the noodles to great lengths without breaking them.

He has also made some ingenious changes to time-tested production techniques, improving the hanging method by splaying the arrangement of chopsticks, which keeps the noodles from sticking together, and building a wind-drying room to minimize weather impact.

Bolstering local economy

His commitment to the noodle has contributed to it being named a time-honored brand by Henan's Department of Commerce in 2015, and its craftsmanship a provincial intangible cultural heritage by the Henan government in 2021.

Liu's business yields 3,000 tons of hollow noodles annually, but after more than two decades at such pace, he began to start feeling his age, and in 2014 decided to pass it on to his son, Liu Honglei.

"At first, I wasn't very interested in making the noodle, but after trying it once under my father's guidance, I gradually took to it," Liu Honglei says.

He remembers how his parents used to stay up all night with the lights on to make noodles.

"Now that I've learned it, I appreciate this traditional craft even more," he says, adding that he has better understood his father's efforts after experiencing the hardships of making the noodle himself.

Liu Honglei has leveraged his youth to help his father's business to break into e-commerce. He started selling the noodle online in 2015, and it was added to the virtual shelves of e-commerce platforms JD and Tmall in 2018.

Online sales now generate nearly 20 million yuan ($2.9 million) in annual revenue, accounting for a quarter of the total.

The booming business has also benefited villagers.

Since 2017, it has paired employees up with impoverished households from the local community, offering free training to hundreds.

It adopts a family workshop-style production approach, in which raw material is distributed and the finished product is then collected, adding between 20,000 to 30,000 yuan to the income of each household, according to Liu Laiwang.

Local government has also given support to hollow noodle development and encouraged it to boost residents' income, and others have followed Liu Laiwang's path, starting up their own Huangchuan hollow noodle businesses.

In 2020, the Zhengzhou University of Light Industry was invited to host an intangible cultural heritage study and training program at Liu Laiwang's factory compound.

The program has offered tips on product packaging design, online sales, marketing, livestreaming and brand image development for more than 20 hollow noodle production enterprises and cooperatives in Huangchuan county.

"It has helped our noodles reach a wider market," Liu Laiwang says.

To date, more than 2,000 locals are employed in the noodle business in Huangchuan, with annual output value reaching 600 million yuan, according to local authorities.

Liu Laiwang's intangible cultural heritage workshop has been selected as one of 66 exemplary cases supporting rural vitalization by the Ministry of Culture and Tourism, the Ministry of Human Resources and Social Security, and the National Rural Revitalization Administration.

These accolades have given Liu more motivation to carry on his cause.

"Our strategy is to adopt a gradual development approach, focusing on being small yet specialized, refined and strong," Liu Laiwang says.

"We aim to preserve and improve our traditional industry and the products that are deeply rooted in our community, making contributions to poverty alleviation and economic prosperity," he says.

Today's Top News

- Digital countryside fueling reverse urbanization

- 'Sky Eye' helps unlock mysteries of the universe

- China offers LAC development dividend

- Future sectors to receive more play

- Nation sets its sights on export boost

- China to open its door to foreign investment wider