|

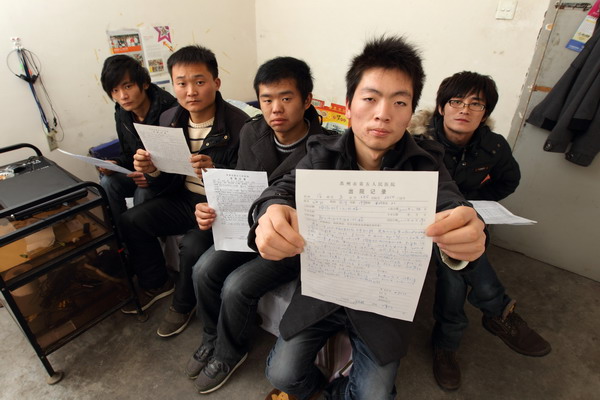

Five men affected by exposure to the chemical n-hexane at an Apple supplier factory in Suzhou, Jiangsu province, display the hospital discharge papers they received following treatment. From left are Sang Xiaolong, Jia Jingchuan, Yao Xiaoping, Zhang Fei and Hu Zhiyong. [Photo/China Daily]

|

While fans eagerly await the release date for iPad 2, which Apple Inc is keeping secret, a Chinese worker in a plant that produces Apple components has his own secret.

|

||||

Employees of United Win Technology suffered muscular atrophy and damage to their nervous system after using a chemical, n-hexane, to clean touch panels from August 2008 to July 2009. The company is owned by Taiwan-based Wintek Corp, which produces iPhone components for Apple.

Apple Inc acknowledged the scandal for the first time on Feb 15, in its Apple Supplier Responsibility 2011 Progress Report. The company said 137 workers at the Suzhou facility had suffered adverse health effects following exposure to n-hexane. The factory has 16,000 employees.

As of Monday, 100 of the 137 had left the factory with compensation of 80,000 to 140,000 yuan ($12,166 to $21,291), according to Liu Jie, press officer for the industrial park where the plant is situated. All signed agreements with United Win Technology that exempt it from responsibility if their health worsens, Liu said.

The cost of China being the world's factory is sometimes paid by workers or the environment, and this is just one of many such instances. But calls for factory owners and big international brands to be socially responsible - to build a greener and safer supply chain and to alleviate harm to workers and the environment - have never been louder, environmentalists say.

As public attention to misdeeds increases, they say, it will be more difficult for these major beneficiaries of "made in China" to dodge criticism.

The workers

As a factory equipment maintenance worker at Wintek's Suzhou facility, Hu Jie works from 8 in the morning till 8 at night, seven days a week. He was diagnosed in January 2010 with damage from n-hexane, but he decided to keep the physical and mental pains to himself until he could be sure everything was all right.

Hu, 31, said he still suffers occasional symptoms of nervous system failure. When he spent time with his family in neighboring Anhui province for Chinese New Year, he said, he forced himself to smile to cover up sudden tingling in his legs.

"I don't want to make them worried. My wife asked me many times about the scandal, but I simply told her I'm not one of the victims."

With a monthly income of less than 3,000 yuan (US$457) - his wife recently lost her job - Hu has to support a family of three and pay 400 yuan a month for his 6-year-old daughter's education.

Hu and the 36 other affected employees who still work at the factory have gotten some help. The local government notified them that 10,000 to 30,000 yuan in disability benefits from the social security fund would be included in their pay, and Hu said he received 15,000 yuan on Saturday.

Many of the 37 are reluctant to undergo follow-up medical examinations offered by Suzhou Industrial Park, said Liu, its press officer. Hu expressed his distrust of the local hospitals.

"Many victims among us have not fully recovered," he said. "We really hope Apple, a global leading company that claims a safe supply chain, can work with its supplier company to have an independent third party appraise our health conditions and give us due and fair treatment."

Many other affected employees were hospitalized and received medical treatment. Hu considers himself less fortunate because he was prescribed only medication and continued working at the factory.

The local hospital deemed his condition not serious enough for hospitalization, he said. "Six months later, I stopped taking the medication when the company stopped paying for it, but I'm almost sure that I'm still not quite right."

Hu said he still feels occasional pain in his left leg, and his left little finger is always numb. He said he also has become easy prey to colds and fever, which makes him think his immune system might have weakened. But that's not the worst, he said.

"Above all, I seem to have lost grip upon my life. I cannot make plans for my future, as I'm not sure to what extent my health conditions will allow them," Hu said. "I have no other choice but to continue working at the factory for fear the disease will return and the ensuing high costs of medication, which I cannot afford on my own."

Although Apple said in its supplier responsibility report that a majority of the 137 workers had returned to work at the factory, 100 chose to leave with one-time compensation.

Yao Xiaoping, a 22-year-old from Shaanxi province, said the first thing he did after discharge from the hospital eight months ago was to negotiate with the company for compensation. "The company said I can only get that on a promise of leaving the factory and signing an exemption agreement, which means the company would not take any responsibility if my health conditions worsened in the future."

Yao finally decided to quit in November, with 90,000 yuan in compensation.

He returned to his hometown in Xuzhou and is still recuperating. Yao said his legs and hands still feel numb and that he is always tired after "very little physical exertion. I will try to find a new job after full recovery, although I'm not sure how long that would take.

"To be frank, I don't know what to do if the worst is to come," Yao said. "The compensation would be a drop in the ocean for medical treatment of the disease."

|

Customers line up to buy the iPhone 4 at the Shanghai Apple Store (file photo, 2010). Taiwan-based Wintek Corp, which produces iPhone components for Apple, owns United Win Technology, whose plant in Suzhou was the site of n-hexane poisoning of 137 employees. [Photo/Agencies]

|

Risks of n-hexane

Eighteen months since the first employee in Suzhou was diagnosed with n-hexane damage, victims are still struggling to learn the truth about their health and are grappling to adjust to a life shadowed by unknown challenges ahead.

N-hexane is a colorless liquid with a slight pungent smell. Its potential risks and safe exposure limits are well known in the industry. Chronic exposure can cause extensive peripheral nervous system failure. Symptoms include tingling and cramps in the arms and legs, followed by general muscular weakness.

N-hexane also is highly volatile at room temperature.

Lang Juming, deputy secretary for social affairs at Suzhou Industrial Park, told Xinhua News Agency that the park gave clear notice two years ago to tenant factories that they could not use n-hexane, and all the companies signed letters of commitment.

But United Win Technology had decided in August 2008 to switch from alcohol to n-hexane for cleaning because it dried more quickly, according to later investigations by local government. Investigators also found that the chemical was used without proper ventilation.

"It now appears we cannot believe the commitment made by the enterprises," Lang said.

The government should play a stronger part in effective enforcement, Lang said, taking pre-emptive measures to prevent accidents rather than just punishing those that violate safety or environmental regulations.

Problematic suppliers

In its supplier responsibility report, Apple admitted it has encountered many problems - including underage workers, involuntary or debt-bonded labor, and unsafe handling of dangerous chemicals - during its audits of 127 production facilities in China. Despite requests from environmental groups in China, Apple declined to list its suppliers.

"Apple's recent supply chain scandal is not an isolated case in China," said Qin Zhigang, General Electric's environmental health safety director in North Asia. "Supply chain problems usually boil down to one specific link, instead of the whole chain at fault."

But international corporations are realizing that China is demanding changes in corporate responsibility, Qin said. "The intensity of public criticism signals a growing environmental awareness among the Chinese. Violations have always been there, but people never showed such strong reactions before."

Who's responsible?

In 2009, Shanghang Huaqiang Battery was linked to the lead poisoning of 121 children in Fujian province. Local authorities found that sludge and industrial wastewater were discharged directly into sewers.

The company was a key equipment manufacturer for Narada Power Source starting in 2007. On its website, Narada identified itself as a supplier for Vodafone, British Telecom and other mobile telecom brands.

On July 5, 2010, Vodafone responded to a British media inquiry about issues raised by environmental non-governmental agencies in China.

In a statement, Vodafone recognized "the seriousness of the pollution incident associated with Shanghang Huaqiang Battery Co Ltd", which was never "a direct supplier", but "supplied product parts to Narada Ltd, which are a direct supplier to Vodafone".

Narada ended its relationship with Shanghang in September 2009.

Legal responsibility in cases like this falls on the local supplier, not the international company that contracted for the work, said Wang Canfa, a professor at China University of Political Science and Law in Beijing who offers free legal aid to victims of pollution.

"It's more of an issue of corporate social responsibility rather than legal responsibility for multinational corporations," Wang said.

Zhu Xiao, a law professor at Renmin University of China, said that when violations occur, victims would be hard-pressed to collect evidence to prove that international corporations were directly involved.

Many international corporations, as standard procedure, require a third-party audit showing their suppliers have certain credentials for quality control and worker safety. However, many suppliers lack the capacity, skills and incentives to improve working conditions and protect the environment, said Ma Jun, who leads the Institute of Public & Environmental Affairs (IPE).

Chinese NGOs have started to use information to improve China's environment, Ma said. IPE provides a public, online database of air and water violations by factories throughout China.

From 2006 to September 2010, the database had compiled a "blacklist" of more than 69,000 environmental violation records of Chinese companies. Of those, 340 companies have communicated with IPE, explaining the violations. Fifty multinational corporations and manufacturers took corrective action and accepted IPE-supervised environmental audits.

Ma said IPE has submitted proposals to lawmakers in Beijing to require corporations to disclose information about toxic chemical releases and waste management activities. IPE's hope is that it can build a database similar to the Toxics Release Inventory in the United States. Such a program, Ma said, would help industry, government and NGOs make informed decisions about industrial and environmental safety.

A customer's nudge

Suppliers hope they can get more support on environmental matters.

"Factories cannot afford the expensive water treatment facilities on their own. It's government's responsibility to set up the sewage treatment infrastructure," said Zhang Minghan, owner of Hanjiang footwear maker. Wal-Mart Stores Inc buys 15 percent of Hanjiang's output.

Zhang's factory used to rely solely on septic tanks to treat the sewage that its 1,200 workers produced. After being singled out by local environmental authorities, Zhang received a strong nudge from Wal-Mart to find a better solution.

Zhang explained the difficulties his factory faced when it comes to environmental protection. His factory was 600 meters from government-funded sewage pipelines. In May 2009, he applied for an extension of the sewage system, and was included in December 2009.

Wang Canfa from China University of Political Science and Law said business and industrial associations in China should also play a more active role in supervising their members.

"Chinese consumers' awareness on choosing green products needs to be improved as well," Wang said. "They have to realize they are making the votes and can influence companies to make the right decisions."