State Grid Taizhou Power Supply Company: Insulator-inspection robot enters pilot operation

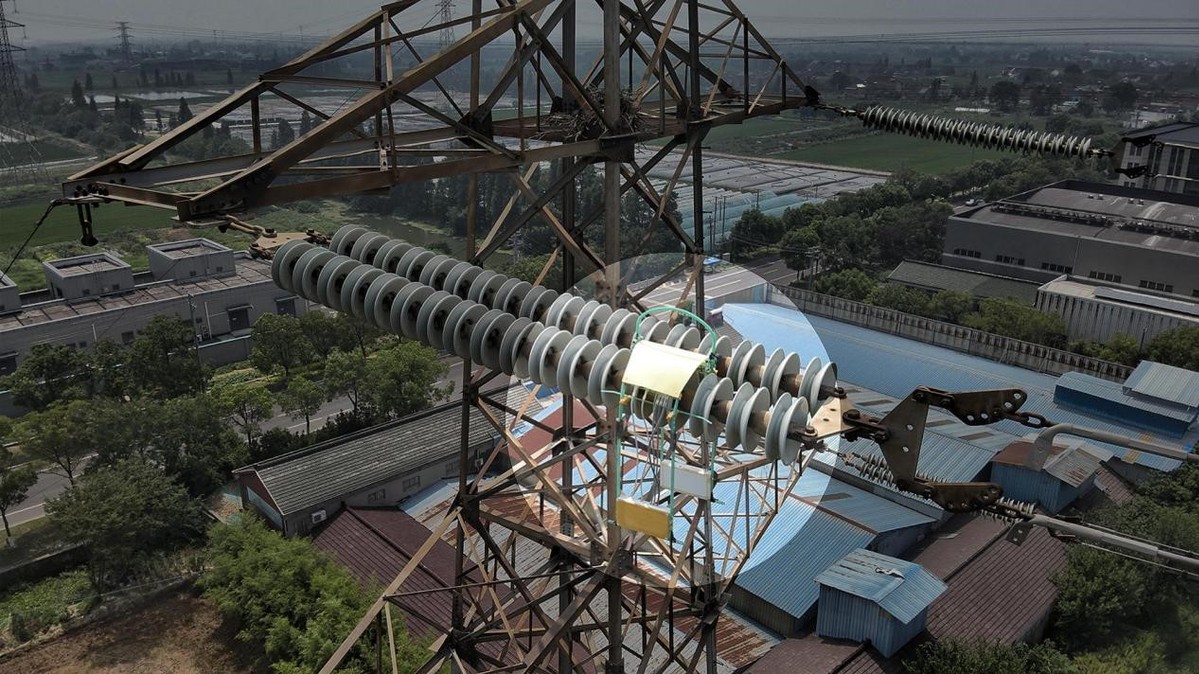

On Aug 15, under the remote guidance of overhead-line maintenance engineer Liu Hai from State Grid Taizhou Power Supply Company, a newly developed insulator-inspection robot began pilot tests on the de-energized 220 kilovolt Shuanghai transmission line. Liu's handheld terminal displayed real-time results: "653 MΩ—PASS" as the robot extended its probe toward an insulator before advancing to the next unit and continuing the sequence.

The robot was jointly designed by the company's Overhead-Line Maintenance Center and UAV Operations Center in July. After it is precisely deployed onto the target insulator string by a multi-rotor UAV, the robot is remotely operated from the ground via a ruggedized tablet. It navigates autonomously along the string while measuring insulation resistance, then streams the data back to the operator. Thanks to a single-string mounting system and a rotatable, self-aligning probe, one deployment is sufficient to inspect both insulator strings on a double-string tower.

Insulator condition assessment is a critical maintenance task that identifies degraded (low- or zero-value) units before they jeopardize line integrity. Traditionally, technicians climbed the tower and tested each disc manually—a process requiring more than an hour for a 220 kV double-string tower. The robot reduces inspection time by nearly 50 percent and eliminates exposure to working-at-height hazards.

State Grid Taizhou Power Supply Company has now initiated live-line trials to verify the robot's electromagnetic immunity under operating conditions. The success of these tests will lay the groundwork for broader deployment of this Jiangsu-grid innovation across the provincial network.