Photo

Co-processing pioneers spread the word across China

By Song Ping (China Daily)

Updated: 2009-12-24 07:49

|

Large Medium Small |

|

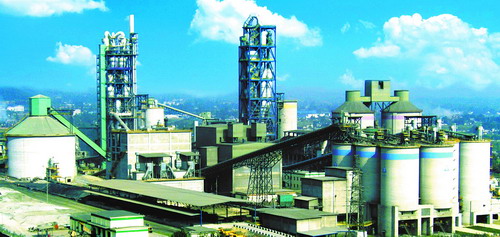

Dujiangyan Plant of Lafarge Shui On Cement Ltd, one of the partners of the Sino-Norwegian project. Yang Shizhong |

The management of massive amounts of industrial and hazardous wastes is one of the major challenges facing China. It is also a bottleneck for a number of heavy industries. As part of addressing this problem, many developed countries have now taken the environmentally friendly option of co-processing this waste in cement kilns, rather than using less ecologically-sound incinerator plants. China, too, is now on the verge of embracing this alternative.

This co-processing has proven to be an effective means of treating industrial and hazardous wastes. Its implementation, however, takes some time, but there are already several businesses pioneering its use.

Beijing Cement is one such pioneer and has now become the largest treatment facility for hazardous wastes in Beijing. Its existing facilities have an annual capacity to co-process 80,000 to 100,000 tonnes of waste and can accommodate wide range of substances on the National Hazardous Wastes List.

Another such early-adopter is the Ningbo Shunjiang Cement Co Ltd, which specializes in the treatment of industrial sludge using the co-processing approach. In 2006, a total of 22,782 tonnes of heavy metal sludge were processed and, in the first four months of 2007, around 11,546 tonnes of waste were treated.

Guangzhou Zhujiang Cement Co Ltd has developed an expertise in treating the most typical waste products, including waste plastics and pre-treated leather. Its process involves classifying, sifting, drying, crushing, packaging and deploying to ensure the quality of its cement and the protection of the environment.

In addition to the above companies, other sites are also adopting the approach. In Sichuan, two businesses are jointly running a co-processing project - the Nanshan Cement Plant of Lafarge Shui On and the Fuhuang Cement (Group) Co Ltd. Another such joint venture involves the Dalian Onoda Cement Co Ltd and the Shanghai Wan'an Enterprise General Corporation. Together they dispose of a range of waste products using co-processing in cement kilns to replenish fuels and raw materials. This has proved not only environmentally safe but also economically viable.

To ensure safe practices in the future, China has taken various strategic approaches to promoting co-processing projects. On September 28, 2006, China signed an intergovernmental agreement on co-processing in cement kilns, part of an international cooperation project. Several domestic projects have also been undertaken, all aimed at dealing with a range of waste products. China is now committed to promote such programs in a bid to solve its waste pollution problems in an environmentally sound fashion.