Weihai company sets new benchmark in wind turbine blade technology

As the wind power industry advances toward larger, more efficient turbines, Weihai-based Weihai Guangwei Composites is gaining attention with its advanced carbon beam technology. The company's latest innovation, used in wind turbine blades, has earned a spot in the provincial list of manufacturing excellence, underscoring its technological and manufacturing breakthroughs.

The carbon beams, essential in turbine blades, are designed to endure extreme wind conditions while providing enhanced durability and reduced weight. Guangwei's team has made a significant breakthrough by customizing resin systems to extend service life and production cycles, while maintaining top performance. Additionally, the company has used its in-house carbon fiber production to optimize the design from the ground up, enhancing product efficiency and adaptability.

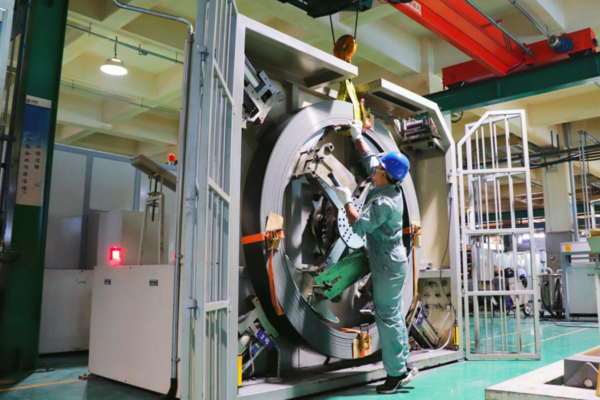

Weihai-based Weihai Guangwei Composites' latest innovation, used in wind turbine blades, has earned a spot in the provincial list of manufacturing excellence, underscoring its technological and manufacturing breakthroughs. [Photo provided to chinadaily.com.cn]

This approach not only reduces the weight and cost of wind turbine blades but also contributes to the global shift toward larger, more efficient wind farms. The carbon beams, which weigh only a quarter of steel but are 7 to 9 times stronger, exemplify the balance of strength and lightness.

As a key supplier to global wind energy giants like Vestas, Guangwei Composites is not only driving the growth of the wind energy sector but also helping Weihai develop a leading carbon fiber composite industry cluster, establishing it as a crucial hub in China's renewable energy landscape. (Edited by Hu Kaili)