Still Made in China, thanks to new tech in swimwear

Xingcheng, a relatively small coastal city in Northeast China, has made a mark for itself on the global map. Nearly one-third of the residents of this city of just over 500,000 people are engaged in the swimwear industry. In fact, the swimwear sector in Xingcheng churns out 170 million pieces of swimwear annually, which is valued at 15 billion yuan ($2.13 billion).

This industry cluster boasts a history of more than 40 years, tracing its origins to family workshops. After decades of focused development, China's largest swimwear production hub has captured one-quarter of the global market share. To get a sense of the scale, one in every four swimwear items sold worldwide is made in Xingcheng.

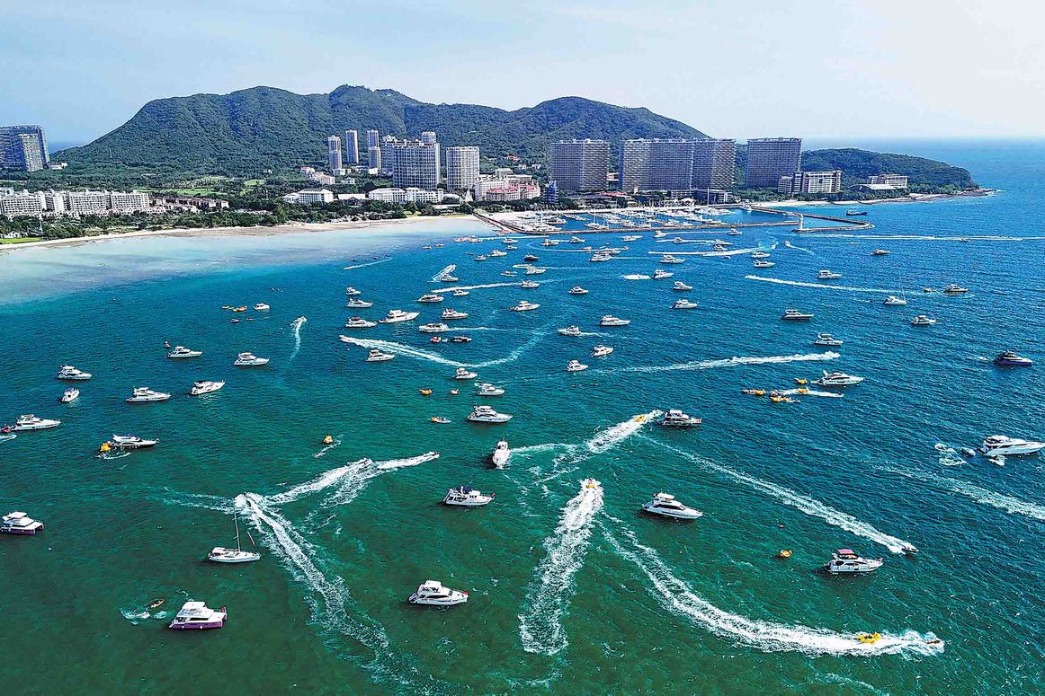

Xingcheng, situated outside Shanhai Pass in Liaoning province, even hosts an annual International Swimwear Expo to propel the industry toward greater scale, branding, and internationalization. This clustered production model also ensures prosperity; women workers in the swimsuit industry earn an average monthly income exceeding 10,000 yuan.

However, this traditional labor-intensive manufacturing cluster is facing significant macroeconomic headwinds, including labor shortages due to population aging and growing international trade uncertainties. How is the cluster proactively coping with these structural challenges?

Looking ahead to 2026, these pressures are expected to intensify rather than fade. Whether Xingcheng can sustain its global competitiveness will increasingly depend on how effectively it upgrades its production and marketing model.

Xingcheng's comparative advantage lies in online sales, particularly in the international market. A core requirement of e-commerce trade is the "small-order, quick-response" model, which mandates rapid innovation and frequent, up-to-date online product imagery. The cluster's intrinsic characteristic of being "small and fast" aligns perfectly with the market demand, constituting its key competitive edge. Compared to larger southern enterprises that favor bulk orders, Xingcheng's approach — featuring small batches, low inventory, and production based on actual sales — is significantly more agile.

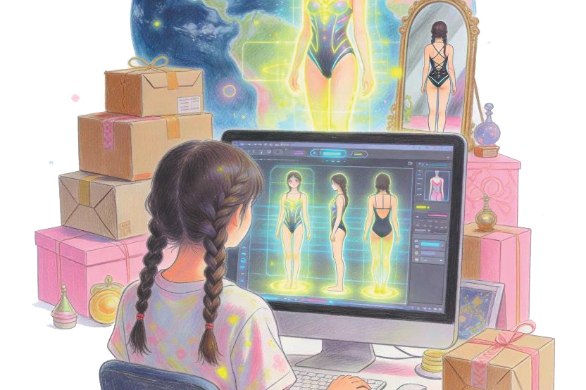

Despite this operational agility, international online sales face a substantial cost and time challenge. For export products, once a pattern was finalized, the physical sample had to be shipped to a modeling agency, Western models had to be hired for a photo shoot, and only then could the product be listed on the e-commerce platform.

However, given that beauty is a scarce good, this process was extremely expensive. The entire cycle consumed at least one month and cost approximately 20,000 yuan, rendering it prohibitive for many small and medium-sized enterprises.

In the era of artificial intelligence, entrepreneurs recognized these significant pain points in design and marketing. One company leveraged AI technology, and now it can launch thousands of swimwear styles every month, complete with photos of models sporting the swimwear and 3D displays, reducing the cost per photo to less than one yuan.

After the Paris Fashion Week, AI can even abstract the latest fashion elements and apply them to swimwear, designing multiple samples simultaneously. Through AI design, 3D pattern-making, and 3D sampling, customers' product ideas can be realized visually and quickly. If a product becomes a bestseller, the enterprise can swiftly organize production, including outsourcing a portion to other companies. This flexible design and production model has dramatically enhanced the competitiveness of Xingcheng's swimwear.

China has thousands of industrial clusters, many targeting consumer goods. Xingcheng's case demonstrates that the application of AI holds great potential for empowering traditional manufacturing clusters, particularly those dealing with fast-cycle, small-order products sold online. We anticipate there will be more AI applications in the design and marketing stages across these clusters, which will make their products more appealing to international consumers. Despite the headwinds of an aging population and trade uncertainty, Chinese entrepreneurs are effectively capitalizing on the benefits of AI to overcome these challenges and secure the cluster's future. "Made in China" may continue to hold an edge in the international market in the foreseeable future.

The author is chair professor of economics at Guanghua School of Management, Peking University. This piece is based on a recent field visit to Xingcheng.

The views don't necessarily represent those of China Daily.

If you have a specific expertise, or would like to share your thought about our stories, then send us your writings at opinion@chinadaily.com.cn, and comment@chinadaily.com.cn.