Production upgrades steer BMW toward success

As the new China-made BMW X5 becomes a hit after its launch in late March, consumers may be concerned about whether its production can meet demand, especially amid the new round of COVID-19 outbreaks.

Last week, BMW Brilliance sent a reassuring message to consumers with its opening of a newly upgraded production facility, an extension of its Dadong plant in Shenyang, Northeast China's Liaoning province.

The Dadong plant is the Sino-German joint venture's first plant, which has symbolic significance for its development. The upgraded plant is expected to provide solid production strength for the innovative and high-quality X5, and also lay a foundation for BMW Brilliance's future product upgrading.

It also means BMW's long-term strategy of continuous investment in China has achieved new results, according to the automaker.

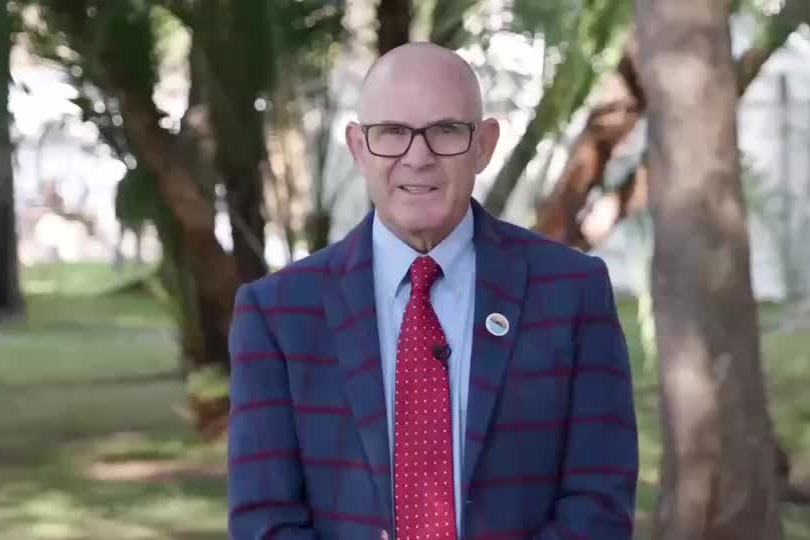

Milan Nedeljkovic, a member of BMW Group's board of management responsible for production, said: "Plant Dadong proves the strength of our team. Despite the challenges of the last three years, this complex construction project was completed fully on schedule."

"Our Chinese production sites are highly significant for the BMW Group. Last year, almost one in every three BMW cars delivered around the world was manufactured in Shenyang," Nedeljkovic added.

Franz Decker, president and CEO of BMW Brilliance, said: "In China, we are determined to lead from the front: lean, green and digital! Building on over 100 years of BMW manufacturing experience, we have established one of China's most advanced and intelligent production bases here in Shenyang. Driven by new technology and our innovation mindset, we strive to create even greater value for our customers. With the new extension, Plant Dadong again sets the benchmark for efficient, sustainable, digitalized and agile production."

The newly upgraded plant meets the BMW's iFactory principles of lean, green and digital, embraces flexible production of fuel-powered vehicles, plug-in hybrids and electric cars and uses innovative production techniques to help reduce the effect of factories on the environment.

"At home in China"

In 2021, BMW Brilliance's Shenyang production base set a record, despite challenges including the COVID-19 pandemic and an auto chip shortage, with an output of more than 700,000 vehicles, making the automaker the biggest among domestic premium car manufacturers.

Besides the newly introduced all-new BMW X5, the Dadong plant produces the X3 and 5 Series for the Chinese market. It is also the only plant that produces the fully-electric iX3 for the global market.

The joint venture's other production facility in Shenyang, the Tiexi plant, manufactures 1 Series, 3 Series, X1 and X2.

This summer, the automaker will have its third vehicle-making plant completed in Shenyang, which will be responsible for the production of the i3, an electric sedan that BMW designs exclusively for the Chinese market.

By then, the automaker will have four plants in Shenyang-three vehicle plants and a powertrain plant that produces both high-voltage batteries and internal combustion engines.

Since 2010, BMW Brilliance has invested around 83 billion yuan ($13.03 billion) in Shenyang to build a production system integrating research and development, procurement, powertrain and vehicle production, making Shenyang the largest production base of BMW in the world.

With the continuous expansion of the Shenyang production base, BMW Brilliance will further promote the high-quality and sustainable development of China's auto industry, and support the development of high-end manufacturing and industrial upgrading in Liaoning, according to the automaker.

High-quality Development

The newly upgraded plant in the automaker's Shenyang production base covers an area of 910,000 square meters. It is equipped with three process workshops of press, body, paint and an assembly workshop with two independent production lines.

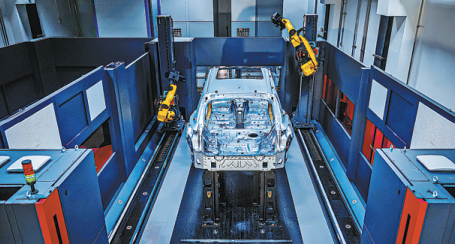

The body workshop is equipped with industrial robot manufacturer Kuka's largest robot, TITAN, with a loading capacity of up to 1.3 metric tons, which ensures the stability of a car's body with an action repeat accuracy of 0.1 millimeters.

The Dadong plant has also had a substantial digitalization upgrade. Data science, artificial intelligence and virtual planning are opening up new dimensions in its automobile production, making it faster, more precise and more transparent and taking efficiency, flexibility, sustainability and quality to an entirely new level.

Process control and various parameter data are monitored and analyzed in real-time throughout the entire production process chain, allowing potential problems to be detected and resolved quickly.

Further investments have also been made in sustainability. With nine new railway transportation lines, the Dadong plant is now home to the most railway transport routes among all BMW plants. Nearly 80 percent of finished BMW vehicles from Shenyang are wholly or partially transported by the railway, which help reduce carbon dioxide emissions compared with traditional transportation methods.

The press workshop in the Dadong plant offers sorting and recycling of aluminum and steel, thereby contributing to the further reduction of CO2 emissions.

The solar photovoltaic system in the Dadong plant has also been upgraded. This year, its 179,000 sq m of solar panels are expected to generate more than 21 megawatt hours of green electricity. At present, the automaker's Shenyang production base has built 290,000 sq m of solar panels, ranking first in scale among enterprises in Liaoning.

Today's Top News

- Momentum builds in A-share market

- China stands firm against maritime intrusions by US, Philippine vessels

- Games souvenirs fostering friendships

- Xi's ecological vision provides global solutions

- US annual human rights circus show exposes its hypocrisy and political bias

- New market entity data show vitality