Toy business is not a game

EU manufacturers feel US tariff pain but keep faith in China, Zheng Wanyin reports in London

When United States President Donald Trump said in April that children in the country will maybe have "two dolls instead of 30 dolls" and "the two dolls will cost a couple bucks more than they would normally", several Western media outlets interpreted the remarks as an admission: his tariffs on China could lead to a toy shortage and costlier products for the US and Europe alike.

China has long been the world's largest toy producer and exporter, and a tariff war with such a manufacturing powerhouse has undoubtedly also hit European toymakers, many of whom have production facilities in, as well as a substantial sales revenue from, China.

European companies that outsource manufacturing to China and export to the US bear the brunt of the knock-on effects, facing declining demand from US buyers. Even those toymakers that do not sell directly to the US may end up shouldering part of the losses borne by Chinese manufacturers as they struggle with fewer orders.

However, companies found that shifting factories away from China is not child's play.

John Baulch, publisher and managing director of the United Kingdom trade publication Toy World Magazine, identified three key advantages that give China an edge over alternative locations for European toymakers: capacity, infrastructure and expertise — a combination that, currently, "no other country in the world has got".

"China has an established network of factories, a huge choice of factories," he said. "So the capacity there is huge. Then you look at the logistics infrastructure within those countries. Other countries will have factories, but do they have road connections from the factories to the ports? Do the ports have capacity? Are they on the shipping route with the same volume of ships that China has?"

Liang Mei, president of the China Toy and Juvenile Products Association, a nonprofit trade association with more than 5,000 registered members, added that the toy industry in China is highly clustered, with major hubs in southern Guangdong and eastern Jiangsu and Zhejiang provinces boasting complete industrial chains that offer everything needed for production in one place.

What China has built is an "all-around infrastructure" that allows it to produce large volumes of goods within the required turnaround time for Europe, Baulch said, a result of a long-term effort, one that other hubs are catching up with, but are still a "long, long way behind".

A trusted destination

This decades-long development has also endowed the country with expertise, making it a "trusted manufacturing destination", Baulch said. "You can rely on the quality, the pricing, the turnaround time, everything that you need to rely on. You can also rely on the fact that if an issue arises, China has the knowledge to sort it out."

Peter Handstein, founder and CEO of Hape Toys, a German toy company, echoed this sentiment, saying that the supply chain in China is "unbeatable".

"This did not happen overnight. I am not only a witness. I am a part of it," he said.

Hape Toys has manufactured the majority of its toys in China for the past three decades, since its production facility in Zhejiang's Ningbo opened in 1995. Its office in China, which employs more than 1,000 people, now oversees all core operations, from toy design and material sourcing to manufacturing, product inspection and distribution.

Artificial intelligence and robotics are further powering factories, Handstein said, enabling tasks such as quality checking.

Some have been hyping up the idea that soaring labor costs in China are eroding its competitiveness, while Handstein described the increase as an "achievement" because paying labor 10 times more means the wealth of a worker in China has increased 10 times.

Low cost was the catalyst for the rise of the manufacturing giant, but what has kept China in the game is its reliability and quality, Baulch said.

"People forget that, in the last 20 years, China has made tremendous strides at improving the quality… When you send your toys there, the vast majority of the time, you are going to get exactly what you ordered and paid for."

Producing in high-quality plants in China is indeed not cheap, but the sector is capable of meeting some very specific needs, said Juan Martinez, founder of Art Fabula, a Swedish toy brand whose toy prototypes are made in China. He makes a type of sofubi toy, a style of vinyl collectible toy, and the product must also comply with all European Union legal standards.

The one-man company had attempted to relocate part of the manufacturing operation elsewhere, away from China, but the effort proved to be a costly "disaster" that nearly destroyed the small business.

"Everything was wrong … I lost all hope when I received broken toys in the mail, along with the metal molds!" Martinez said.

Economic setback

For Martinez and many other small and medium-sized enterprises, or SMEs, that underpin the European toy industry, tariffs pose a serious setback, as the US administration imposed new or increased tariffs on imports from multiple countries, including the EU, as well as Southeast Asian countries like Indonesia and Vietnam, which are emerging manufacturing hubs.

According to the EU's executive body, the European Commission, 99 percent of EU toy manufacturing companies are SMEs, which account for 61 percent of employment in the EU's toy industry, providing more than 50,000 jobs.

It is believed that the US uses tariffs as a tactic to revive US manufacturing, while Radhika Desai, a professor in the Department of Political Studies at the University of Manitoba in Canada, said the industry decline and outsourcing are more of a result of deliberate policy choices that the US had been aware of, and even happy about.

"Capital has been given the freedom to do whatever it likes," she said. "Instead of sourcing goods that they want to sell to the American people from American companies that have higher labor costs, they have decided to source them from elsewhere …Instead of increasing productivity in other ways, which would allow capitalists to pay good American-level wages, they have preferred to have things produced by cheaper labor … That is what has caused the deindustrialization of the US. There have not been any countries cheating them."

Crucially, toys are usually aimed at children; therefore, both Baulch and Handstein highlighted that the goods are often only subject to minimal taxes.

Even during Trump's first term, when China was the main target of his tariff policies, toys were spared.

"What we're hoping is that politicians can come to an agreement, so we can get back to doing what we do best, which is selling toys and making kids happy," Baulch said.

Today's Top News

- Shield machine achieves Yangtze tunnel milestone

- Expanding domestic demand a strategic move to sustain high-quality development

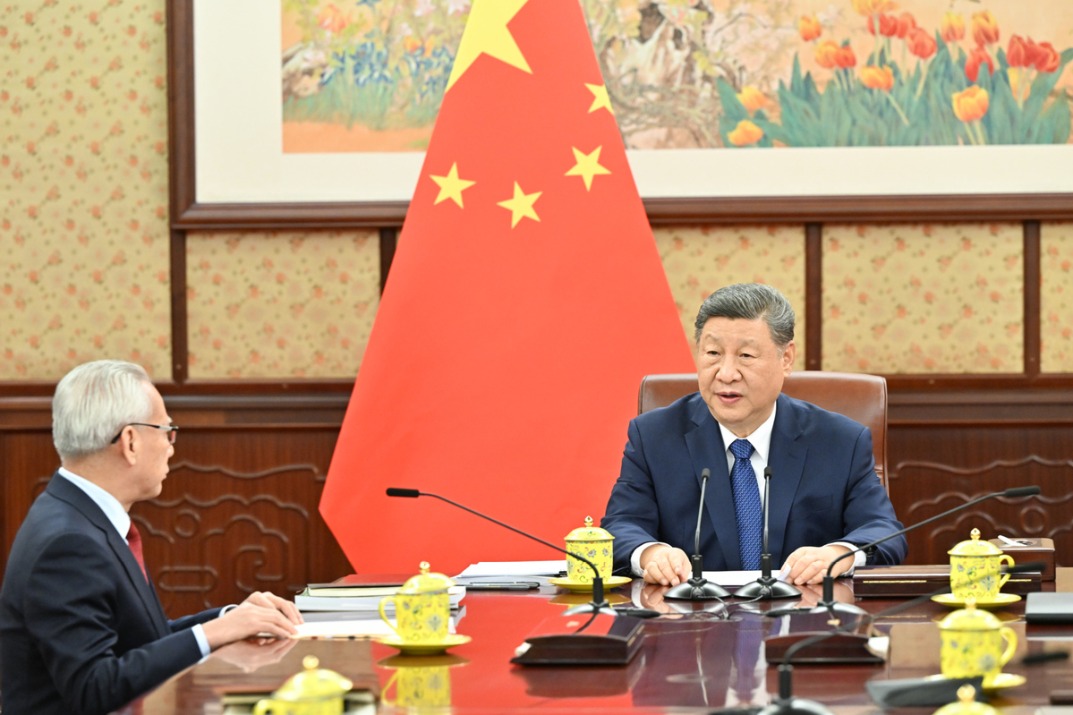

- Xi hears report from Macao SAR chief executive

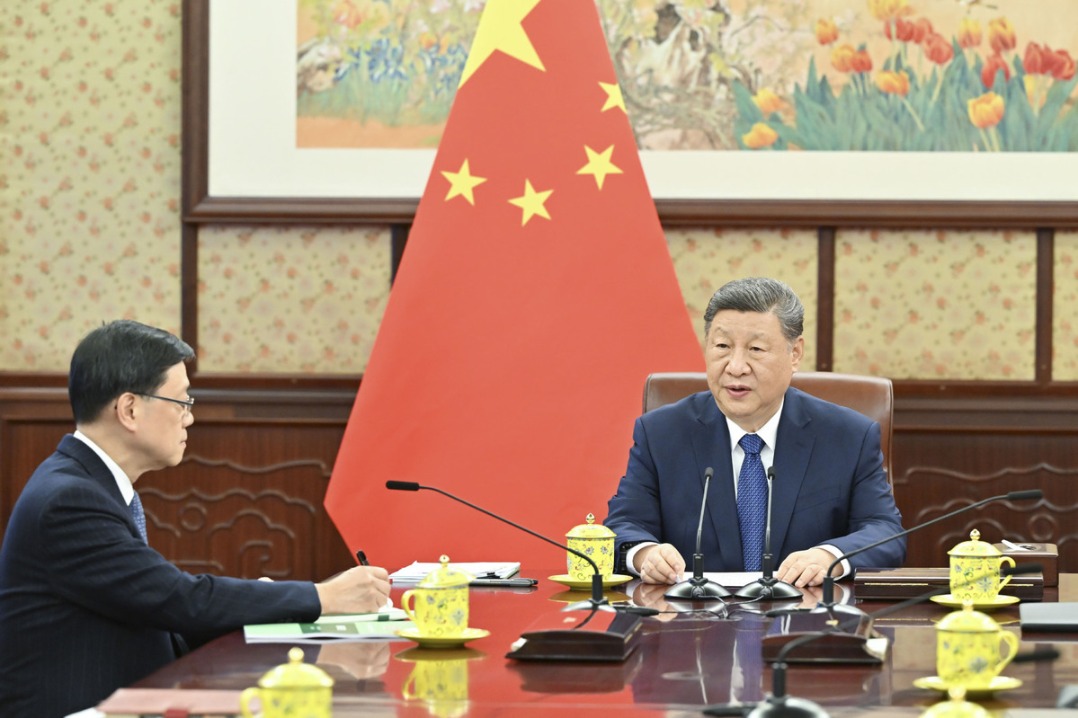

- Xi hears report from HKSAR chief executive

- UN envoy calls on Japan to retract Taiwan comments

- Innovation to give edge in frontier sectors