Wujiang's innovation ecosystem evolving rapidly

From robotics to 3D printing, district in Suzhou home to more than 100,000 private enterprises, including two that have broken into Fortune Global 500

At the heart of China's Yangtze River Delta region, there is a place where the elegance of a traditional water town coexists with the pulse of cutting-edge innovation.

In Wujiang district of Suzhou, Jiangsu province, one can stroll along ancient canals flanked by white-walled houses and arched stone bridges before enjoying an "afternoon tea party" with an advanced humanoid robot in a Suzhou garden, using a sophisticated 3D printed tea set and wearing a UV-protective jacket that are all innovatively developed by local tech heavyweights.

This unlikely fusion of heritage and high tech is just one striking example of how technological ingenuity can quietly reshape the future.

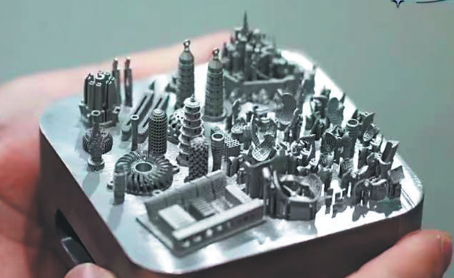

Inside ZRapid Tech's 3D printing technology factory, an intricate model of a miniature city is on display as a showcase of what's possible with advanced metal 3D printing.

"Some parts of the model's finest parts are just 0.1 mm, barely visible to the human eye or camera, yet fully formed with 3D printing," said Xing Zhanwen, the company's deputy general manager. "Our printing precision now reaches 0.02 mm, finer than a strand of hair, leading the industry in this field."

Besides the sophisticated metal printing technology, ZRapid Tech has also achieved another milestone in resin 3D printing, and it is all developed in-house.

"We've created one of the world's fastest and largest 3D photopolymerization printing systems, capable of producing objects up to 2.7 meters in size," Xing said, adding that the technology is already being applied in home appliances, high-speed railways, construction and other sectors.

With more than 150 patents and a complete industrial chain covering materials from polymers to metals and ceramics, the Wujiang-based tech company has spent the past 14 years leading the field in additive manufacturing.

Xing attributed the company's continued innovation to its R&D-driven approach, with nearly 40 percent of its staff engaged in R&D and related expenses accounting for 13 percent of annual revenue.

"Wujiang's location in the heart of the Yangtze River Delta region gives us easy access to talent, capital and application scenarios. It's a natural fit for the expansion of high-end manufacturing like 3D printing," Xing said.

With a population of over 1.5 million, Wujiang is now home to more than 100,000 private enterprises, including two that have broken into the Fortune Global 500.

As Wujiang's innovation ecosystem continues to evolve, it is now home to 77 national-level "little giant" tech enterprises specializing in niche and advanced technologies. According to government data, the district's total R&D expenditure was estimated to account for about 4.15 percent of its GDP last year.

Wujiang's spirit of innovation extends beyond 3D printing. Following robot technology company Leju Robot's launch of its first humanoid robot production line in Wujiang late last year, the first of its kind in Jiangsu, the company said it plans to continue developing and manufacturing its flagship robots in the district, with full capacity expected within five years.

Once scaled, the line is expected to generate an annual output value of 300 million yuan ($41.73 million).

Among China's first batch of open-source HarmonyOS-based humanoid robots capable of traversing complex terrain, Leju's KUAVO series is able to realize intelligent deployment across diverse real-world scenarios.

With the successful delivery of its 100th full-size humanoid robot this January, Leju now leads the world in both quantity and diversity of real-world humanoid robot deployments. In addition, its KUAVO robots are also operating stably on factory lines such as at Chinese car brand Hongqi, further bridging the gap between robotics R&D and industrial application.

According to Xu Tianshu, a professor at Suzhou University of Science and Technology's business school, private enterprises are key players in driving innovation, and those of different sizes play varying roles along the industrial chain.

"While large firms often take the lead in breakthrough innovation, smaller and medium-sized ones can focus on their core strengths and contribute essential specialization and support services to major enterprises, large-scale projects and entire industrial chains," Xu said.

However, he also stressed that private businesses, given their vast number and scale, are most concerned about being treated equally in economic policy and market practice.

To address the concerns, China's first basic law dedicated to the healthy development and legitimate right of private sector — the Private Sector Promotion Law — officially came into effect on May 20.

The law includes a specific chapter on science and technology innovation, encouraging private enterprises to play an active role in advancing frontier technologies, cultivating new quality productive forces and developing a modern industry system. It also aims to provide stronger legal support for private businesses striving to overcome technical bottlenecks.

Wei Dong, director-general of the private economy bureau at the National Development and Reform Commission, called the law a milestone that would "optimize the business environment and energize high-quality growth" for private enterprises across the country.

Data from the State Administration for Market Regulation showed that as of the end of September 2024, the total number of private-sector market entities in China reached 180.86 million, accounting for 96.37 percent of all market entities and marking a year-on-year increase of 3.93 percent.

The private sector serves as "capillaries" of China's industrial and supply chains, playing a vital role in stabilizing growth, employment and livelihoods, said Zhang Daoyang, a senior official at the SAMR.

Zhang added that the new law's nine chapters and 78 provisions, based on principles of equal treatment, fair competition and shared development, are expected to empower private businesses with greater certainty and protection.

For private business owners like Xu Derong, president of the Shengze Textiles brand promotion association and chairman of Suzhou Romrol Fashion Group in Shengze town of Wujiang, the message is clear.

"We studied the law as soon as it was released," Xu said. "As a private entrepreneur, we'll seize the opportunities brought by the Private Sector Promotion Law, strengthen independent innovation and harness the textile industry's advantages to lead the next chapter in high-quality development."

In the Wujiang High-tech Zone of Shengze, which has long been known as China's traditional silk hub, innovation is now being woven directly into the fabric.

At the display area of local textile firm Lixintex, rows of its self-developed high-performance textiles are neatly arranged.

The company's latest sun-protective fabric uses an innovative weave of nylon, spandex and enhanced polyester to achieve both UV resistance and breathability, a useful dual-performance innovation for summer weather.

"With an ultraviolet protection factor rating of 50+, the fabric blocks over 95 percent of UV rays, while the ultra-fine yarn and special weaving technique ensure it remains light and airy," said Luan Yong, the company's R&D director.

Luan also highlighted other innovative products, such as a "solar-charged heat-retaining" textile that can warm by 3-5 C under sunlight, and a lightweight down jacket material created by combining functional membranes with down powder through 3D printing, providing strong insulation without bulk.

The eye-catching innovations are a reflection of a broader shift in Shengze's traditional silk industry toward high-end textile manufacturing.

"Focusing on the transformation of the textile industry toward high-end, intelligent and green development, Shengze is actively encouraging enterprises to drive progress through independent innovation by upgrading equipment, improving technologies, and expanding investment and production," said Chen Yu, Party secretary of Shengze town.

Now as one of China's top production hubs for chemical fiber fabrics, Shengze hosts more than 2,500 industrial textile companies and over 10,000 textile trade firms, with industrial output above a designated size totaling 22.6 billion yuan in the first four months of this year, according to the township government's data. Flagship companies like Hengli Group and Shenghong Group, both Fortune Global 500 firms, anchor the thriving ecosystem.

According to Xu, the strength of Shengze's textile industry lies in its tightly knit industrial and supply chains.

"Over 90 percent of our fabric innovations are developed in-house by the nearly 100 member companies under the association," Xu said. "This cuts inventory costs by at least 15 percent across the supply chain, upstream and downstream. That's what makes 'Shengze Textiles' a name worth trusting."

Today's Top News

- Wake-up call for Europe to review its dependency: China Daily editorial

- China reports 5% GDP growth in 2025

- Return capsule of Shenzhou XX safely returns to Earth

- Sanya rises as magnet for Russian tourists

- China's steady opening-up for Asia-Pacific economic growth

- Blueprint seen as a boon for entire world