BMW boosts recycling in circular economy bid

While the electrification of the automotive industry is reducing tailpipe emissions, resource scarcity and environmental pressures from battery manufacturing are creating new challenges. It is a problem faced by the entire auto industry, to which premium carmaker BMW Group is providing its own solution.

During the third BMW Group China Sustainability Summit, held in Wuxi, Jiangsu province, on Monday, the carmaker released a comprehensive report covering its seven entities in China. It showed industry-leading achievements in not only CO2 emissions reduction, but in resource preservation, waste reduction and material circularity.

Jochen Goller, president and CEO of BMW Group Region China, said at the forum: "The Circular Economy is the most sustainable type of economy. At BMW Group, we have put circularity at the center of our sustainable development."

Circularity is one of the three core pillars of BMW's vision for future mobility, Goller said. The other two are electric and digital.

"The world is built on 'ands', not on 'ors'. The future of our planet depends on finding the right balance between the environment and common prosperity, between creation and reduction, between society and industry," Goller said.

A high priority of BMW in China is its water resource management. The carmaker recognizes the significant challenges posed by climate change to freshwater resources, especially given the water-intensive nature of painting in vehicle manufacturing.

According to the report, BMW uses just 1.77 cubic meters of water per vehicle produced in its manufacturing processes in China, which is equivalent to the capacity of a standard London telephone booth.

For comparison, the average carmaker in Europe consumes 3.5-4 cu m per unit produced, nearly double that of BMW in China.

Franz Decker, president and CEO of BMW Brilliance Automotive, said: "When it comes to green manufacturing, we are already at the forefront of our industry."

"Water conservation is especially important for us, as less than 20 percent of China's water resources are located in North China (where the BBA production base is located)," he said.

At BMW's Shenyang production base in Northeast China's Liaoning province, which is the German carmaker's largest production site worldwide, the carmaker utilizes cutting-edge technology to minimize freshwater consumption.

An example of water stewardship is its state-of-the-art recycling system at the Dadong plant extension within BMW's Shenyang production base. Multiple filtration processes separate, break down and remove organic matter and contaminants. This raises wastewater to a quality suitable for reuse in production, enabling the carmaker to achieve closed-loop water management.

The paint shop at the Dadong plant has achieved freshwater-free production. In 2022, the plant saved more than 150,000 cu m of water, enough to supply nearly 1,000 local households for a year.

Because of these results, BBA was recognized as one of the Ministry of Industry and Information Technology's first National Industrial Wastewater Recycling Pilot Enterprises in 2022.

Beyond its manufacturing plants, BMW has extended its commitment to water conservation along the value chain.

The third BMW Group China Sustainability Summit took place at the Xibaohang 4S store in Wuxi. Equipped with a rainwater harvesting system, it is the first Green Star Lighthouse dealership in China recognized by BMW. It has a capacity of up to 200 metric tons and a landscape water pool with a storage capacity of 160 tons, allowing for the maximization of rainwater resources.

BMW launched the Network Transformation Green Star program for dealers in China in 2022. It encourages sustainable actions at dealerships in four aspects: Green Power, Green Operations, Green Environment and Green Engagement.

Water management is one of the criteria. Green Star dealerships have to feature efficient fixtures, clean drinking water systems, and car wash water recycling and treatment equipment.

More than 200 BMW dealerships are expected to meet the Green Star Standard by the end of this year and BMW aims for its entire dealer network to go green by 2026.

The carmaker has also been conducting corporate social responsibility projects to protect water resources.

As part of its BMW Beautiful Homeland Initiative, the carmaker is protecting biodiversity at the Liaohekou Nature Reserve. Liaohekou is less than 200 kilometers from Shenyang and one of China's major wetland areas.

Similar to its management of water, BMW has adopted a circular approach in utilizing other resources. The company explained that "the art of circularity" means using raw materials from the cars of yesterday to build the cars of tomorrow.

In China, the company has been collaborating with its partners to recycle materials from retired batteries, use recycled aluminum in wheels, and promote the application of recycled plastic parts.

In 2022, BMW Brilliance recycled more than 60,000 tons of scrap metal in production. In the same year, 10,318 high-voltage batteries were recycled at the dealers.

"We are looking forward to joining hands with even more partners to promote China's green development, build the circular economy and create a joyful planet for all of us," Goller said.

Today's Top News

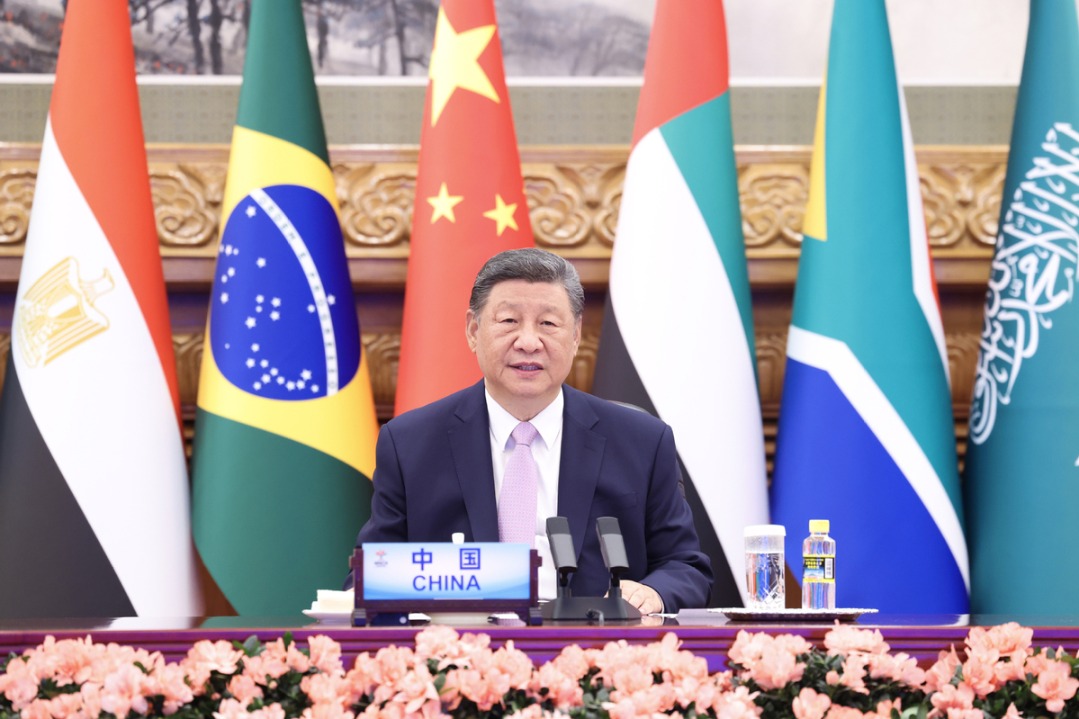

- Xi extends congratulations to Kim over DPRK's 77th founding anniversary

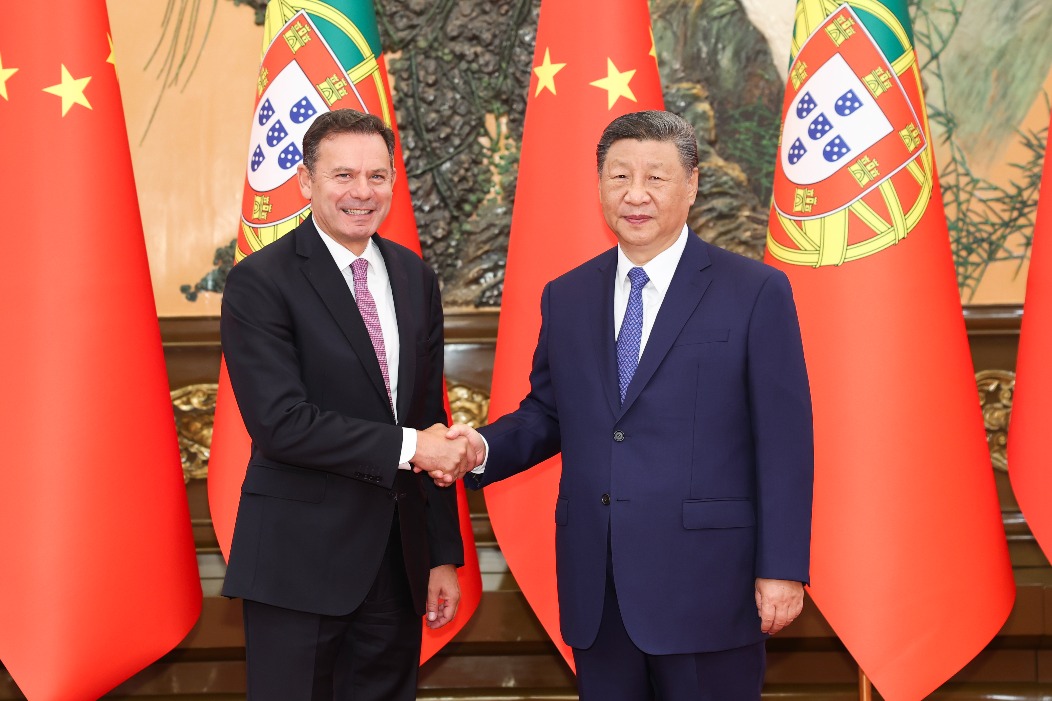

- Xi meets Portuguese prime minister

- Autonomous regions making good progress on multiple fronts

- Trade fair highlights broadened opening-up

- New markets to spur foreign trade

- Global Governance Initiative a timely call