Domestic demand will offset manufacturers' flight

Taiwan's Hon Hai Precision Industry Co., whose Chinese mainland subsidiary, Foxconn Industrial Internet, is the world's largest contract electronics manufacturer and a major supplier for Apple Inc, has said it will gradually increase production capacity outside the mainland.

Hon Hai Precision Industry Co., a contract manufacturer of electronic goods for the United States, now has 70 percent production capacity on the mainland, besides having factories in India, Brazil, Mexico, Vietnam, Indonesia, the Czech Republic, Australia and other countries. Its move must therefore be guided by comprehensive considerations, and does not threaten the mainland's status as the "world's factory".

It is no secret that in recent years, because of rising costs, some manufacturing enterprises, especially labor-intensive ones, have relocated their production bases from the mainland to countries such as Vietnam and Mexico. Cost-sensitive enterprises have particularly accelerated such flights after the United States threatened to impose higher tariffs on Chinese products.

Shortly after he took office, US President Donald Trump called on Apple to return its manufacturing base to the US and put pressure on Hon Hai Precision Industry Co. and Taiwan Semiconductor Manufacturing Company to build factories in the US. The two enterprises promised to invest in the US, but have not started production there yet, given that information and electronics products manufacturing has a complex supply chain system and requires a large number of skilled engineers, which the US does not have.

However, because of the US government's requirement that government procurement or important components of key enterprises should not be "made in China", some Taiwan companies on the mainland have shifted some of their production for goods that are exported to the US.

After the outbreak of the novel coronavirus, the US called on companies to relocate production bases from China to US ally countries. Some did set up backup capacity in other countries. Apple headphones, Microsoft laptops, and Google phones are being made in Vietnam. India has launched an enormous investment program encouraging Samsung and other electronics manufacturers to set up assembly lines there.

Some manufacturing enterprises have moved production bases from the mainland to other countries, but they still remain within the mainland's supply chain. For example, India's electronics, pharmaceutical and other industries are heavily dependent on the mainland's supply chain. Taiwan's contract factories, whether based in Southeast Asia or in India, still rely on the mainland's engineers and managers.

The active deployment of 5G communication infrastructure and industrial internet and the development of informatization, automation and intelligence in China will continuously boost the production efficiency and innovation capacity of China's manufacturing industry and weaken the labor cost factor.

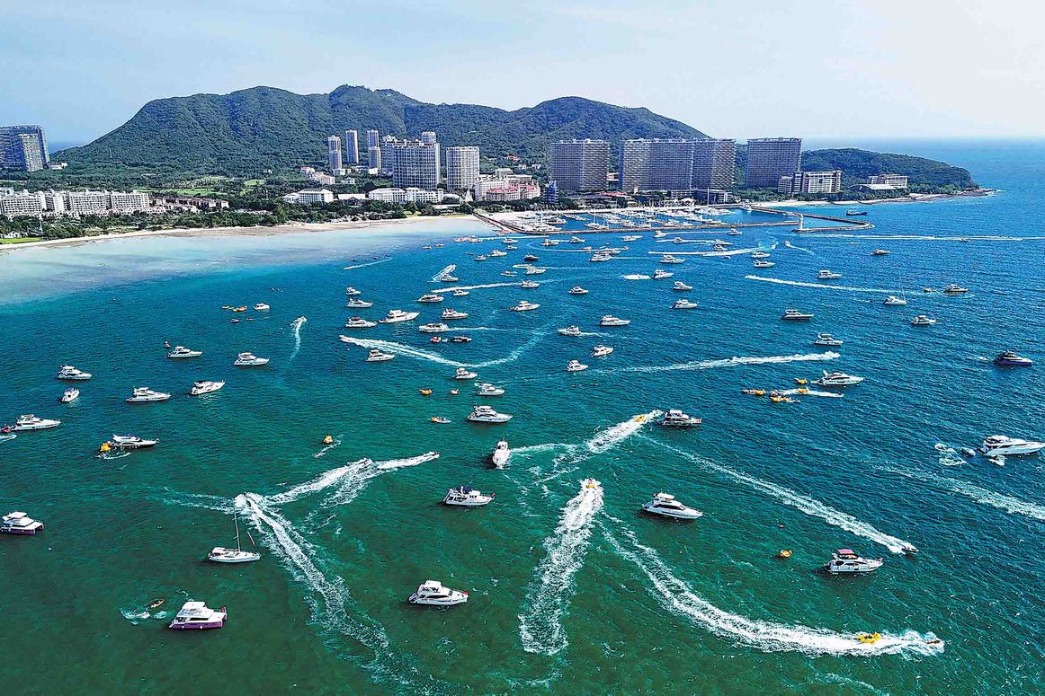

As China has increasingly become a domestic demand-driven economy, the relocation of some manufacturing export capacity overseas will have little impact on its economy.