China's 'Optics Valley' ready for the long haul

The electronics and optical communication equipment manufacturing industry in China is likely to see pressure in the short term as the novel coronavirus outbreak might have an influence on the normal production of related companies in Wuhan, capital of Hubei province, but the impact will be temporary, said industry insiders.

Wuhan is not only a megacity with a population of more than 10 million, but also a crucial link in China's manufacturing industry chain. A string of technology companies have set up their factories in Wuhan.

Foxconn Technology Group, the world's largest contract electronics manufacturer and a key Apple supplier, said it was confident of achieving its production targets despite the virus outbreak. The company has a manufacturing facility in Wuhan, the outbreak's epicenter.

"Foxconn is closely monitoring the current public health challenge linked to the coronavirus and applying all recommended health and hygiene practices to all aspects of its operations in the affected markets," the company said in a written statement.

"Our facilities in the Chinese mainland are following holiday schedules and will continue to do so until all businesses have resumed standard operating hours," it said.

Foxconn did not comment on its specific production practices but confirmed that "we have measures in place to ensure that we can continue to meet all global manufacturing obligations."

According to a work report of the Wuhan municipal government, optoelectronic information, automobile and parts, biomedicine and medical equipment are the three pillar industries of the city, with the revenue of the main businesses exceeding 500 billion yuan ($71.5 billion) in 2018.

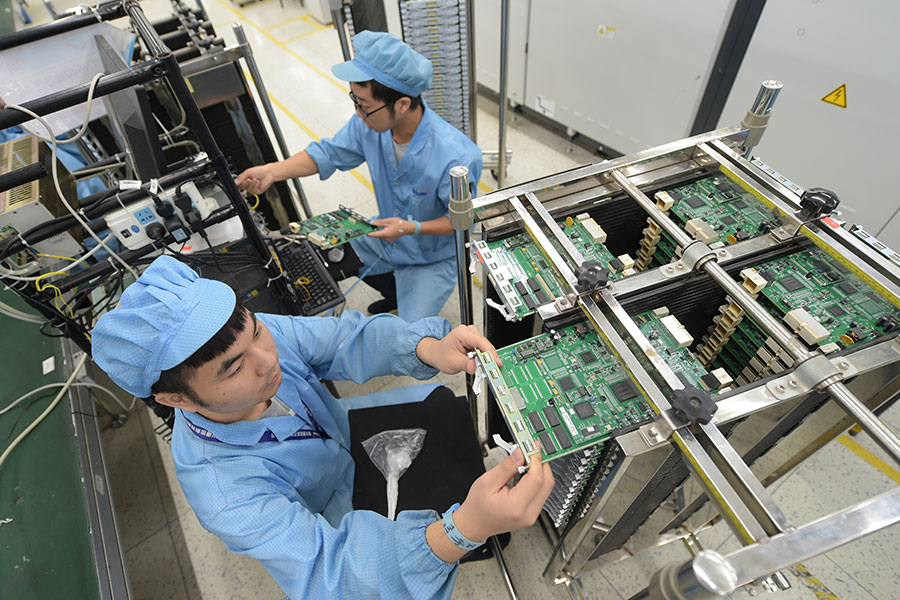

The Wuhan East Lake High-Tech Development Zone, known as the "Optics Valley of China", is now among the most innovative and fastest-growing regions in Central China.

Lenovo Group Ltd, the world's largest personal computer maker, said the company is confident in its ability to minimize the novel coronavirus' negative impact on its business, thanks to its global manufacturing and sales layout as well as the use of cutting-edge technologies to automate production.

Lenovo, which has one of its biggest plants in Wuhan said it has taken a string of actions to respond to the virus, and donated all IT equipment necessary for the special treatment center in the city.

Yang Yuanqing, chairman and CEO of Lenovo, said the epidemic and its resultant delay in restoring production will inevitably have a short-term impact on Lenovo, but the company's global manufacturing and sales network and its sprawling presence in the world will help the company minimize potential impact of this outbreak on consumers.

Wuhan-based chip manufacturer Yangtze Memory Technologies Co Ltd said it has given top priority to the staff 's security, postponed the return time of non-local employees, as well as promoted telecommuting in the face of the epidemic.

Meanwhile, the company, which concentrates on the design, production and sales of NAND flash memory chips, is scrambling to ensure the normal operation of production lines by actively coordinating the raw material supply and logistics services. It has paid attention to the development of the ongoing epidemic and will try its best to minimize the negative impact.

"The epidemic will affect the manufacturing and supply of electronic components and equipment in the short term, as many factories will not resume production after the Lunar New Year holiday until Feb 10," said James Yan, research director at Counterpoint Technology Market Research.

Yan said the delivery and logistics, as well as the upstream and downstream enterprises in the industrial chain will also be influenced. However, such impact will not last long and may end in March, along with the resumption of production and expected decline of infection cases, he said.

China Star Optoelectronics Technology Co Ltd, a leading TV panel supplier and a subsidiary of home appliances giant TCL, has a sixth-generation flexible display panel production line in Wuhan. The project produces high-resolution, flexible and foldable display panels for smartphones.

"We have put the health and safety of our staff first since the outbreak of the novel coronavirus," said Li Dongsheng, TCL founder and chairman, adding the company has stepped up health checks at its factory and set up a quarantine dormitory. It will continue to popularize and disseminate the information about the prevention and control of the novel coronavirus.

The Gen 10.5 TFT-LCD production line of BOE Technology Group entered operation in Wuhan in December 2019. The company said its annual production capacity will decline due to the outbreak, but it will minimize the impact by adjusting the operation strategy and strengthening cooperation with upstream and downstream enterprises.

Xiang Ligang, a telecom veteran and director-general of the telecom industry association the Information Consumption Alliance, said Wuhan plays a vital role in country's optical communication segment, and the impact on related fields is expected to be temporary and controllable. "Moreover, the high-tech industry is not labor-intensive and there is no need to gather large number of workers in the factory."