Using wood and mortar to build a peculiar home

Updated: 2012-08-12 07:53

By Michael Tortorello(The New York Times)

|

|||||||

|

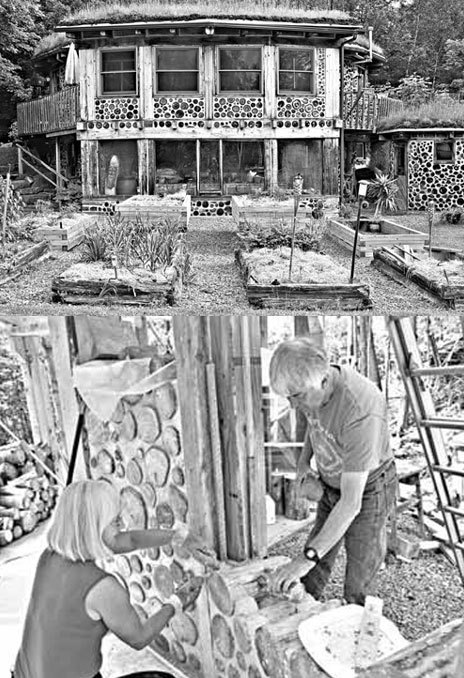

Earthwood, in upstate New York, was built using cordwood masonry. Rob and Jaki Roy laid cedar logs into a wall. Photographs by Tony Cenicola / The New York Times |

WEST CHAZY, New York - Rob and Jaki Roy have been building for 30 years. And they have been writing and lecturing on their craft at their Earthwood Building School here, about 20 kilometers west of Lake Champlain and south of the Canadian border, for just as long.

Their peculiar building method, which employs sticks and mortar, is called cordwood masonry. Its earthy alchemy: creating a masonry wall with short lengths of exposed wood in place of brick or stone.

As Mr. Roy said, "If you can stack wood, you can build a cordwood house."

The Roys contend that the practice is suited to all types of people: low-income landowners and vacation-home dreamers, energy-efficiency fanatics and back-to-the-landers.

A cordwood wall looks the same inside and out: the logs go all the way through. And the houses' shaggy green roofs, cozy dimensions and folksy finishes make them more suited to the country than any urban setting.

For most cordwood practitioners, Mr. Roy, 65, said, "it's a means of building the kind of house they want for an affordable price." If you can manage the labor, and shop for supplies in the Dumpster, a new cordwood home can be built for just $20 a square foot (about 930 square centimeters), he said. That's a quarter of the average price for a contractor-built home, based on recent American census figures.

Census data indicate that owner-built housing starts dropped steeply during the endless recession. Yet attendance at the Earthwood school has doubled in the last year, to 40.

There may be 200 to 300 cordwood homes and outbuildings in construction (and about 1,500 completed) across North America, said Richard Flatau, who wrote the new book "Cordwood Construction: Best Practices" and runs workshops and a Web site about the subject.

William H. Tishler, a professor emeritus of landscape architecture at the University of Wisconsin, has traced some of the earliest cordwood structures back to the hardscrabble settlements of the mid-to-late 19th century.

Traditional log cabins and timber-framed dwellings required "extensive lengths of straight, high-quality timber," Mr. Tishler wrote in "Cordwood Building: The State of the Art." The material for a cordwood house could come from skinny, second-growth lumber, even fire-charred forests.

The professor searched for the origins of the building method in Scandinavia, Germany and Canada before concluding that the best place to find old cordwood is probably Door County, Wisconsin.

Nick Hylla, who lives in Custer, Wisconsin, said the glaciers that trudged across the Niagara Escarpment left behind a giant limestone ridge: the material for lime putty mortar. And the north woods teemed with white cedar.

Mr. Hylla, 36, is the executive director of the Midwest Renewable Energy Association, a nonprofit group that holds an annual alternative-building expo. And so he mated this old-fashioned skeleton to modern equipment: a solar space-heating system, with a 75-centimeter sand bed that stores warmth beneath the floor. The result is an energy bill of just $20 a month.

Over the years, Mr. Roy has built prolifically. Yet the home the Roys have occupied since 1981, Earthwood, is a true showpiece of the back-to-the-land building movement.

The round shape maximizes space. In place of a center pillar, they lodged a 21-metric-ton stone masonry stove. It's a massive radiator in the winter and a heat sink in the summer. They dug into a hill to shelter the bottom floor and planted a green roof to cool the second story. A stationary bike pressurizes the water system, which feeds the upstairs kitchen and bathroom.

The house is bundled in cordwood masonry walls made from salvaged cedar rail. But far more important than the insulation value of the 40-centimeter logs, Mr. Roy said, are the tons of masonry and sawdust infill. This mass buffers the temperature inside.

Mr. Roy and his younger son are building a 20-sided cordwood home in much the same style.

"Northern white cedar is a first choice," Mr. Roy said, adding that "white pine and spruce are also good choices."

He placed a glop of mortar on top of a log halfway up the wall.

Someone with an artistic eye - that would be Mrs. Roy, 63 - could insert a bottle in the wall for a skylight effect. During the pointing, or finishing, "you can put in glass beads," she said.

"Or seashells," Mr. Roy said.

"Shards of mirror," she said.

"It can get too funky," Mr. Roy said.

"Cordwood can be very forgiving," he added. "But it won't forgive stupidity."

The New York Times

(China Daily 08/12/2012 page12)