Bradwell B marks Chinese industry's transition

LEI XIAOXUN/CECILY LIU

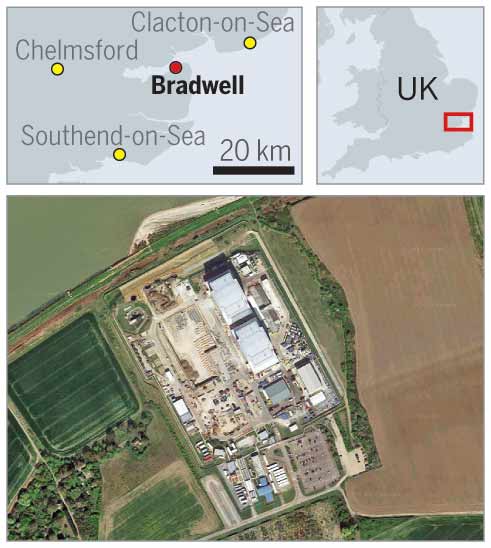

Development at the Bradwell B power plant is progressing well, according to EDF Energy and China General Nuclear Power Corporation, which together are developing a new UK nuclear power station at Bradwell-on-Sea, on the Essex coast.

From 'big' to 'strong', the project sees China's technology embraced by world

Development at the Bradwell B power plant is progressing well, according to EDF Energy and China General Nuclear Power Corporation, which together are developing a new UK nuclear power station at Bradwell-on-Sea, on the Essex coast.

Bradwell will be built with indigenous Chinese third generation nuclear technology -Hua-long Pressurized Reactor 1000 (also known as HPR1000)-- with support from EDF.

CGN and EDF are preparing geographical studies of the site where the Bradwell power generators will be located. These works include checking the soil condition; assessment of cooling facilities and design strategies to protect the local biodiversity, according to Richard Mayson, director of Bradwell Power Generation Company.

As the first nuclear power plant in a developed economy using Chinese technology, Bradwell is expected to pave the way for the international expansion of China's nuclear industry.

"Chinese nuclear technology's deployment in a mature economy, such as Britain, symbolizes Chinese nuclear power industry's transformation from 'big' to 'strong'," said Zheng Dongshan, chief executive of General Nuclear International, CGN's London-based subsidiary.

China's nuclear industry has grown rapidly over the past three decades.

With safe and successful completion and operation of nuclear power plants, such as the famous Daya Bay Nuclear Power Plant in Guangdong province, China is becoming an active leader in global nuclear power development by leveraging its extensive experience and robust technology.

China currently has 36 nuclear power reactors in operation-ranking it fourth in the world after the US, France and Russia-with a further 20 under construction.

The World Nuclear Association forecasts that China will overtake the US with the largest nuclear power capacity over the next 10 to 15 years.

The timing of the Bradwell construction is to be confirmed, but preparation is well on track.

In January this year, the UK's nuclear regulator started a process to review HPR1000 for UK deployment.

Known as the General Design Assessment, this test is said to be the strictest globally. That means passing the test will open doors for HPR1000 in many more international markets, said Andrew Shepherd, a senior energy and infrastructure analyst at BMI Research.

CGN estimates the GDA review will take five years.

The first phase, which involves CGN delivering to the British regulator a Preliminary Safety Report for the HPR1000 design, is expected to be completed soon.

"The HPR1000 design enjoys the advantages of both maturity and economic efficiency," said Mao Qing, CGN's chief technical officer in Britain.

Mao says HPR1000's technology is mature because it builds incrementally on proven technology, instead of incorporating huge quantities of completely new features. Its economic efficiency is achieved by simplifying some features relative to other earlier third-generation designs, without compromising quality and safety.

Four nuclear reactors in China have been built using HPR1000 technology-two at Fuqing in Fujian province and two at Fangchenggang in Gunagxi Zhuang autonomous region.

Chinese companies are also actively negotiating deals to build HPR1000 stations in Kenya and Egypt.

Peter Haslam, head of policy at the UK's Nuclear Industry Association, said CGN is providing huge economic benefits "locally and nationally" through the Bradwell project.

A large number of British nuclear supply chain companies are preparing to bid for contracts at Bradwell, which would not only bring them immediate financial benefits but also make them a part of the HPR1000 design over the long term, giving them further opportunities as China exports its HPR1000 to other countries.

"We will be approaching CGN as soon as they announce the contract specifications," said Graham Honeyman, CEO of Sheffield Forgemasters, which is looking to secure contracts on forging works for the nuclear power station's pressurizer and steam generator.

British company Amec Foster Wheeler is already working with CGN to provide support for its GDA work, while Hayward Tyler and China's Shanghai Apollo Machinery signed a deal this year to create new nuclear equipment to support HPR1000 in the UK.

The UK's National Physical Lab and the Chinese nuclear company China National Nuclear Corp has created a joint research and development center to support HPR1000's localization process in the UK.

Alongside the supply chain work, CGN is working with British universities, including the University of Sheffi eld, to train UK graduates to work on its projects in China and later in the UK.