HK's soldering techniques may need to change, task force says

Updated: 2015-09-26 08:27

By Shadow li in Hong Kong(HK Edition)

|

|||||||

Experts offer five recommendations to prevent any future contamination of drinking water

Soldering materials which connect pipes were officially confirmed to be the main reason for excessive lead in the drinking water of 11 public housing estates for the first time. This prompted a task force from the Water Supplies Department on Friday to suggest these soldering techniques be abandoned.

Despite the surge in the costs of materials, a veteran industry stakeholder agreed that ending the use of tin soldering materials containing lead or even of soldering techniques would not harm the industry too badly.

The task force, led by the Deputy Director of Water Supplies Wong Chung-leung, examined 134 water pipe parts from two lead-hit estates during the past two months. Dissected copper pipes showed that massive lead deposits were attached to the inner surface.

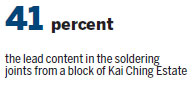

Tests also showed that lead content in the soldering joints from a block of Kai Ching Estate, the first victim of the lead-tainted tap water, reached as high as 41 percent. This is 585 times above the British standard of 0.07 percent.

The water scare first surfaced in July when unsafe levels of lead were traced in tap water from Kai Ching. Further water tests saw another 10 estates facing the same problem. More than 100 residents, mainly children, were found to have unsafe lead levels in their blood. Three committees were set up to address growing public concerns.

Isotope analysis of the lead in different parts of the pipes revealed that 82 percent of lead in water came from the solder joints, while another 18 percent came from the copper pipes. But a member of the task force, Chan Hon-fai, said lead from copper pipes would not mean the industry standard would be exceeded.

The task force also ruled out the possibility that water was tainted before entering the water supply systems in the buildings.

In a further move to tackle the issue, the task force suggested an end to such soldering techniques. Workmen could instead apply pressure or use mechanical bindings to attach pipe joints. They could even use silver soldering materials, Wong suggested. He said the government might consider passing regulations to do this.

Hugo Kam Kwok-leung, representing six major plumbing groups, said the overall cost would go up by 60 percent if soldering materials were changed to silver. Using pressure to connect pipe joints would also double the cost.

Kam believes these suggestions will not hurt the industry in terms of technique requirements or cost. But he suggested the government allow a grace period for it to adapt to the new policy.

Five suggestions were brought forward by the task force to avoid similar incidents in future as well on Friday. Two of them - requiring water tests for four heavy metals at newly-built housing and conducting sampling on soldering materials on sites - were already implemented days after the lead in water incident broke. Experts also suggested regular on-site inspections by qualified engineers and regular examinations of water pipes by X-ray machines.

A centralized purchase for soldering materials to prevent soldering materials containing lead was also suggested. Kam said he supported this as it could be easily traced when problems arose.

Wong Chung-leung admitted the industry had a limited understanding of the real consequences of using lead soldering materials. But Wong also wants a review of the Waterworks Ordinance which was established in 1975.

stushadow@chinadailyhk.com

(HK Edition 09/26/2015 page7)