Out of print

Updated: 2013-10-04 07:16

By Sophie He(HK Edition)

|

|||||||

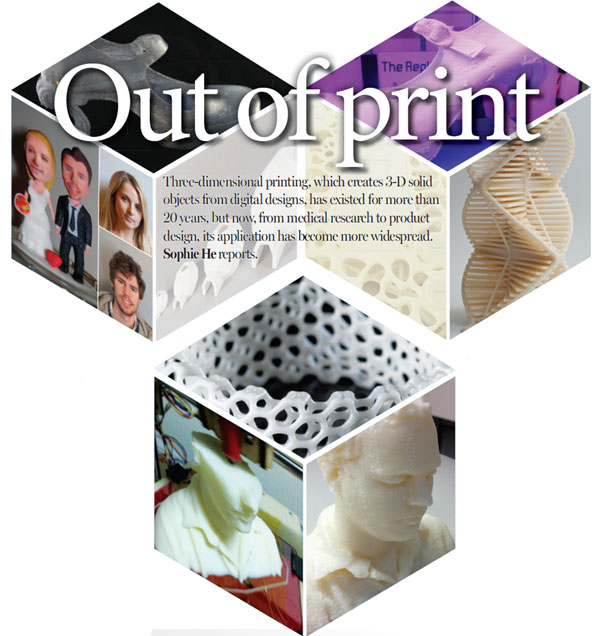

Three-dimensional printing, which creates 3-D solid objects from digital designs, has existed for more than 20 years, but now, from medical research to product design, its application has become more widespread. Sophie He reports.

In Hong Kong, even today, dentists and dental technicians use 3-D CAD/CAM (computer-aided design and computer-aided manufacturing) technology to design and produce dental prostheses. They insert data on the shape and size of the prosthesis needed: the quality of the completed product is greatly improved over what was previously available and the processing time is substantially reduced.

The Hong Kong Productivity Council, HKPC, together with the Department of Mechanical Engineering and the Faculty of Dentistry at the University of Hong Kong, developed the process. They got together to help local firms acquire better dental restoration techniques, via the elaborately named "Development of a Numeric Controlled and User Centered 3-D Dental Prostheses Design and Manufacturing System with Build-In Knowledge Based Chinese Dental Database." The aim, Bryan So Man-kit, senior consultant of the Biomedical Engineering Unit at HKPC told China Daily, was to create a Zirconia-made crown to enhance the quality and precision of dental prostheses.

The 3-D process, still unfamiliar to many people, is already widely used in Hong Kong in several industries, says So. The first 3-D printer, he tells China Daily, was installed at HKPC as early as 1995, to give the city's companies an advantage with product design.

The root of 3-D printing is an additive manufacturing process. Typically, 3-D printers work by building tiny layers of plastic on top of each other to produce a 3-D recreation of a design prototype.

Jonathan Jaglom, general manager of Asia Pacific and Japan at Stratasys Ltd, a Nasdaq-listed 3-D printer manufacturer, said that 3-D printing has many unique advantages in prototyping and manufacturing, as it is an additive fabrication (layer by layer), as opposed to subtractive fabrication, it has no geometric limitation.

Surgical blueprint

"Subtractive fabrication is like making a sculpture. Imagine that you are holding a chisel, removing material in order to get to the part you want, but you can only go as far as your hand can reach. That is the major limitation of subtractive fabrication," said Jaglom.

The process is used primarily by designers for prototyping, toys and mobile-phone cases, for example. Dutch designer Iris van Herpen used 3-D printing to create intricate shoes for the catwalk at a Paris fashion show.

The technology yields fascinating potential, especially customized products for the medical field, including replicas of human body parts that can used be used to train doctors in carrying out surgical procedures.

The 3-D printing process greatly reduces time and cost in product development while simultaneously producing higher quality products.

With an aging population and the growing awareness of the importance of healthcare, global demand for medical treatment and supplies is growing steadily.

The World Health Organization, for example, reports more than 2 million cases of skin cancer every year. Skin cancer has become one of the top-10 cancers in Hong Kong, with numbers growing since 2002.

At present, most dermatologists carry out preliminary diagnoses of skin cancer by visual inspection. The failure rate of these examinations runs as high as 40 percent. HKPC has begun development of a non-radioactive optical 3-D imaging system to help improve diagnostic procedures.

Today, HKPC owns two printers, bought in the last two years at a cost of HK$2 million, but their potential appears almost limitless. Biomedical research is a leading example.

The principal role of HKPC's two printers is to produce prototypes designed by Hong Kong's manufacturers, physicians and individual inventors, he said.

"The cost will be charged according to the size of the prototype, for example, to print out a mobile-phone sized item will cost HK$500, and take only two hours," said So.

On average, he said HKPC receives more than 300 orders for 3-D printing each year, giving some indication of the importance of the technology in Hong Kong.

"They (local companies) also find 3-D printing very helpful, as it helps them shorten the product design period," So said, adding that 3-D printing is also more accurate than handcrafted models and more convenient.

It's also helping many young designers in Hong Kong to produce their designs in small quantities, which would be extremely difficult otherwise. Most factories would be unwilling to take on jobs on such a small scale, and if they did accept them the costs would be enormous.

"Thanks to 3-D printing, designers can have their design work in hand at a very early stage so they can attend exhibitions and explain their designs to other people so, in some way, by using 3-D printing, we also help in protecting designers intellectual property," said So

He acknowledged that there is still enormous scope for 3-D printing to improve, both in terms of its degree of precision, as well as in the selection of materials. Still, the record is pretty impressive, even with complex and lightweight designs. A 3-D printed rocket component survived a hot-fire test, according to NASA.

The US space agency plans to launch a 3-D printer to the International Space Station (ISS) next year, an advance that would allow astronauts to replace lost or broken items without the need - or astronomical costs - of having additional supplies sent up to space. In a more ambitious development still, the agency's labs are 3-D printing miniature satellites that can be shot out of the ISS to relay data back to Earth. More than a humble copier, a 3-D printer will have the convenience of a galactic 7-Eleven on a grandiose scientific and mechanical scale.

Back on terra firma, So believes that demand for 3-D printing in Hong Kong will continue to grow along with the improvement of the technology and HKPC will monitor market demand closely in order to decide whether or when to purchase more 3-D printers.

Cups runneth over

Jonathan Jaglom said that during the past year, more 3-D printable content has been generated and made available thanks to developments in software. Designers need a 3-D CAD file when they go to the printer. Recent innovations in software have made them easier to manipulate.

"For example, if I am designing a cup in a CAD space," said Jaglom, "I can take that file into a 3-D software space, where I can create a large variety of cups, I can do it with two handles, I can make it (the cup) very thick ... I can decide how I want to manipulate the file. All these files are printable," said Jaglom.

Although in the past there were already tens of millions printable files, there are now a lot more. "Thousands of 3-D printable files could appear on the Internet overnight, basically it is infinite, in terms of volume," he said.

'Print me a 3-D printer'

The 3-D printers are also becoming more accessible to the consumer market. Stratasys has bought up MakerBot, the leader in desktop 3-D printing.

MakerBot focuses on the lower-end market. Jaglom said the company did not expect much from MakerBot's retail store at first, since 3-D printers are often used for prototyping, but he says the retail store outlet has proven surprisingly popular with consumers.

Jaglom said its printers are priced between $2,000 to $500,000 and its customer base contains individual consumers to professional design companies.

Given the industry has been recognized and accepted by more people, 3-D printing is considered a promising field, said Jaglom quoting GIA's analysis. The market is expected to grow to $2.99 billion by 2018.

Stratasys, says Jaglom, has more than 8,000 customers globally and shipped a cumulative 32,245 systems worldwide as of June 30, 2013.

It has over 100 staff members in six different offices with regional headquarters in Hong Kong.

"For many years, we have made it clear from a strategic point of view that this is the region we want to be in, and this is the region we want to grow in," said Jaglom, explaining that the pace of growth in Asia for 3-D printing is the fastest among all regions that Stratasys has business in.

"We are very well-positioned in this region to sustain that growth."

Jaglom believes government support is one reason 3-D printing is developing so fast in Asia. The governments of China, Japan, Singapore and Korea, are all assisting local companies to embrace 3-D printing technologies.

One of Stratasys' customers is Adidas, the sports footwear and apparel producer, which refers to its 3-D printers as 3-D fax machines, since the machines enable designers to communicate effectively with their manufacturing base in Southeast Asia.

"Their designers send the file as an e-mail attachment to the manufacturer, who then prints out the file with a 3-D printer overnight. That way, the designer can talk to the manufacturer the next day and be making sure that what the designer wants, the producers can produce," said Jaglom, adding that it saves time and mistakes on all sides.

"3-D printing exists because it gives customers the ability to take part and have a hand in their designs at a very early stage of their product development," said Jaglom.

He recalled that during the financial crisis in 2009, although sales in the industry went down, the decline was nothing close to the general market trend affecting industries as a whole.

Jaglom admits that 3-D printing still has many limitations, a major one being the materials involved.

"The limitation today is how many materials we can replicate in a 3-D space," he said. "Material properties need to simulate real materials, so the closer you are to simulating the end product the more printer usage you will see."

He believes the defining future trend in the industry will deal with materials. 3-D printers will be able to print out "better parts", in terms of quality as well as functionality, he said.

Jaglom told China Daily that dozens of parts inside its most advanced printer are actually produced by the same model of printer. "There will a day, maybe not too far from now, when a 3-D printer will be able to print out another 3-D printer," he said.

Contact the writer at sophiehe@chinadailyhk.com

(HK Edition 10/04/2013 page4)