Jiangmen: A shipbuilding powerhouse

Leveraging its unique geographic position, the city has emerged as a key player in Guangdong's vessel-making industry, as well as a manufacturer of luxury yachts. Chai Hua and Zhang Tianyuan report from Jiangmen.

Editor's note: The month of February marks the fifth anniversary of the publication of the "Outline Development Plan for the Guangdong-Hong Kong-Macao Greater Bay Area". In the third of China Daily's series on the most intriguing stories to come out of the Greater Bay Area cities within the past five years, we explore Jiangmen's strengths in producing ships and yachts, witness the latest developments in making celebrated dried tangerine peels, and visit China's largest underground laboratory for detecting neutrinos.

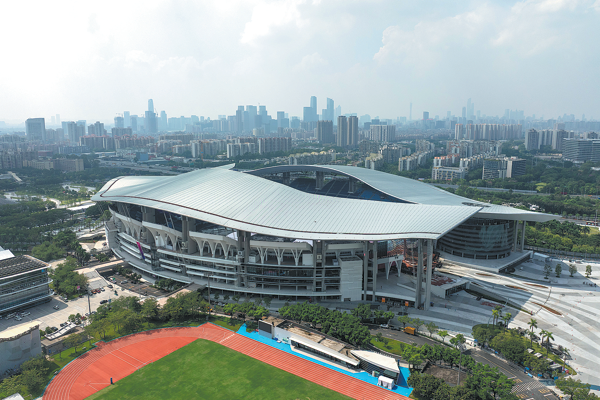

With its long coastline, Jiangmen has been a key hub for the shipbuilding industry in Guangdong province since the Jiangmen Shipyard started in the 1950s.

From January to September, Jiangmen's shipbuilding and offshore engineering-equipment manufacturing business saw an output value of 3.18 billion yuan ($446.1 million), showing steady growth after a remarkable 82 percent surge in 2022, according to government data.

In the 14th Five-Year Plan for the development of the marine economy, the Guangdong provincial government has proposed backing the establishment of intelligent marine engineering equipment research centers and testing centers in Shenzhen, Zhuhai, Zhongshan and Jiangmen. As one of the province's largest shipbuilding hubs, Jiangmen also put forward plans to vigorously develop offshore industries.

Jiangmen aims to strive for a total output value of 5 billion yuan in the shipbuilding and marine engineering equipment sectors by 2025. It's also dedicated to forging the largest marine engineering-equipment manufacturing base in Guangdong. The strategy is to beef up the supply chain and high-end development, and to expand its presence in the international market.

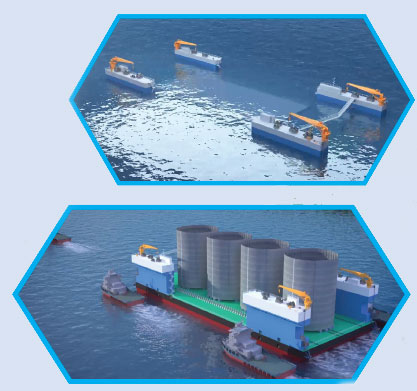

In August, Jiangmen Hangtong Shipbuilding - a subsidiary of the Fourth Harbor Engineering Co at China Communications Construction Co - delivered Sihang Yongxing - a new shallow-draught, semi-submersible heavy transport vessel, which is the largest flat shallow-draught semi-submersible transport barge currently in operation. It demonstrated the city's manufacturing prowess in marine equipment.

The ship, which began construction in 2021, is an enormous undertaking. This colossal vessel features a deck area equivalent to 1.5 soccer fields with four towerlike structures, approximately six stories high, located at each corner.

The vessel can enter ports or estuaries with low water depths and enable the transport of large pipe sections for underwater tunnel construction, shipyards for shipbuilding, and prefabricated platforms for large caissons.

The company, in Jiangmen's Xinhui district, also built the first domestically designed and deep-cement malaxation vessel in China that is considered a "powerful tool" for the foundation treatment construction of coastal ports, wharves, breakwaters, revetments, and artificial-island reclamation.

Wang Chao, deputy general manager of the vessel-maker, says the company has set up five innovative labs for shipbuilding and intelligent equipment manufacturing, as well as a smart electromechanical equipment engineering center in the city.

Intelligent and digitalized manufacturing, and management hold the key to development directions in the future, he says. The firm has invested in a green and automotive assembly line for heavy steel structure products in Gujing town of the district.

In addition to engineering vessels, Jiangmen is home to one of the largest private shipbuilding companies in Guangdong - Jiangmen Nanyang Ship Engineering Co. Established in 2005, Nanyang focuses primarily on constructing modern and energy-efficient small bulk carriers. The company's modern and economical 40,500 DWT (deadweight tonnage) bulk carriers have achieved world-leading performances and are recognized as one of the international standard ship types, commonly referred to as "Nanyang-type" vessels in the global market.

According to local media reports, the company's orders remain robust, extending up to 2026. In 2023 alone, it's scheduled to deliver 13 vessels, with a total estimated output value of nearly 3 billion yuan.

Research and development vital

A unique player in Jiangmen's shipbuilding industry is luxury-yacht manufacturer Heysea Yachts. Started in Jiangmen in 2007, Heysea Yachts is among the few 120 yacht builders nationwide that aims to join the ranks of the world's top 10 yacht-makers.

"About 20 years ago, rumors in the West were swirling that all manufacturing could shift to China, except yacht-making", which represents the pinnacle of craftsmanship, recalls Heysea Yachts Chairman Leng Xuehua. Known for its capability in designing and producing midsize- to large yachts exceeding 80 feet (24.4 meters), the company has been honored as the nation's premier yacht manufacturer multiple times and won the Best Asia-Pacific Superyacht Builder accolade in 2018.

As the size of these luxurious vessels increases, the need for intricate detailing and high standards has become more pronounced, he explains. "The larger the yacht, the more the details matter. For instance, noise and vibration, which are often overlooked in the building of smaller vessels, have become critical factors in larger yachts."

Leng attributes the success to his generous investment in research and development, as well as the exceptional employees, along with the strong manufacturing industry, which experienced a rapid rise following China's entry into the World Trade Organization in 2001. Heysea Yachts channels more than 6 percent of its annual revenues into research and development, with one-third of its workforce composed of technology professionals. This places the company at the forefront of its industry peers in terms of dedication to R&D investment and employees.

According to the annual "Global Order Book", published by Boat International Media, which serves the superyacht industry, the company made it to the top 12th in the global superyacht rankings in 2019.

The COVID-19 pandemic brought a battery of challenges that sapped the dynamics of the company's trading activities. The export volume dwindled from 65 percent to 35 percent because of the stringent pandemic prevention measures, recalls Leng. "In the past, our network of intermediaries and partners in countries like Australia, the United States and France had played a crucial role in our business operations. Yet the past years have seen these international relationships strained, as neither party could visit the other because of the COVID-19 curbs."

However, Leng takes pride in the company's nimble strategy that has pivoted its focus toward the domestic market. "We've now launched sailing catamarans to fill the gap in the domestic market, breaking the European catamarans' monopoly in the Chinese market."

Based in Hong Kong, Heysea Yachts located its manufacturing line in Shadui town in Jiangmen, where calm and deep waters are suitable for avoiding typhoons in its maritime jurisdiction.

Leng also suggests Jiangmen should build a comprehensive supply chain ecosystem for the yacht manufacturing industry. "Perhaps 10 or 20 companies need to work together, each playing different roles within the supply chain. Only when the chain is complete can your production capacity keep up."

Contact the writers at grace@chinadailyhk.com