Next target is to cut costs, make machines locally

Experts have said the development of homegrown world-class ballpoint pen heads will cut the cost of making the tips by roughly 50 percent.

Kui Weiliang, deputy director of the China Ningbo Stationery Association in Ningbo, East China's Zhejiang province, home to one of the leading Chinese stationery enterprises, Beifa Group, says: "The average cost of producing a ballpoint pen is about 0.5 yuan (7 cents). The head costs more than 0.1 yuan, which could be decreased to a maximum of 0.05 yuan when the homemade stainless steel products replace imported ones. When it (specialty steel) is mass produced, customers will be able to buy high-quality pens at a lower price."

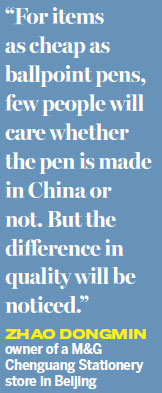

However, Zhao Dongmin, who has run the M&G Chenguang Stationery store in Chaoyang district, Beijing, for about five years, says the price of ballpoint pens would not be affected.

"I don't think the buying and selling price will change," Zhao says.

"The cost saved on materials is likely to be offset by the increasing production and logistical expenses."

In his store, varieties of ballpoint pens are on display. Prices ranges from 1 to 4.5 yuan.

"Generally, customers tend to pay 2 or 3 yuan for a ballpoint pen. For items as cheap as ballpoint pens, few people will care whether the pen is made in China or not. But the difference in quality will be noticed," Zhao says.

Since Taiyuan Iron & Steel Co declared its intention to develop the first homegrown stainless steel unit for use in the production of ballpoint pen heads in early January, the topic has garnered more than 7.5 million page views on Sina Weibo, a Twitter-like social media platform in China.

"The production process for a ballpoint pen head is as complicated as that of a watch. I'm proud China is the sixth country to succeed in doing it," messaged one neitzen.

Fu Yuanlong, deputy director of the National Light Industry Fountain Pen and Ballpoint Pen Testing Center, says ballpoint pen testing has strict standards.

"A qualified ballpoint pen should write 2,000 meters and there should be no broken lines or ink leakage," he says.

"The diameter of the ball is no bigger than one millimeter. And it should be matched perfectly with the ball seat to let the ink flow from the gap between."

Fu says that since the tiny head requires high-precision stainless steel and high-end equipment, China had been importing them from Japan and Switzerland for many years, causing the high production cost.

(China Daily Africa Weekly 01/20/2017 page25)

Today's Top News

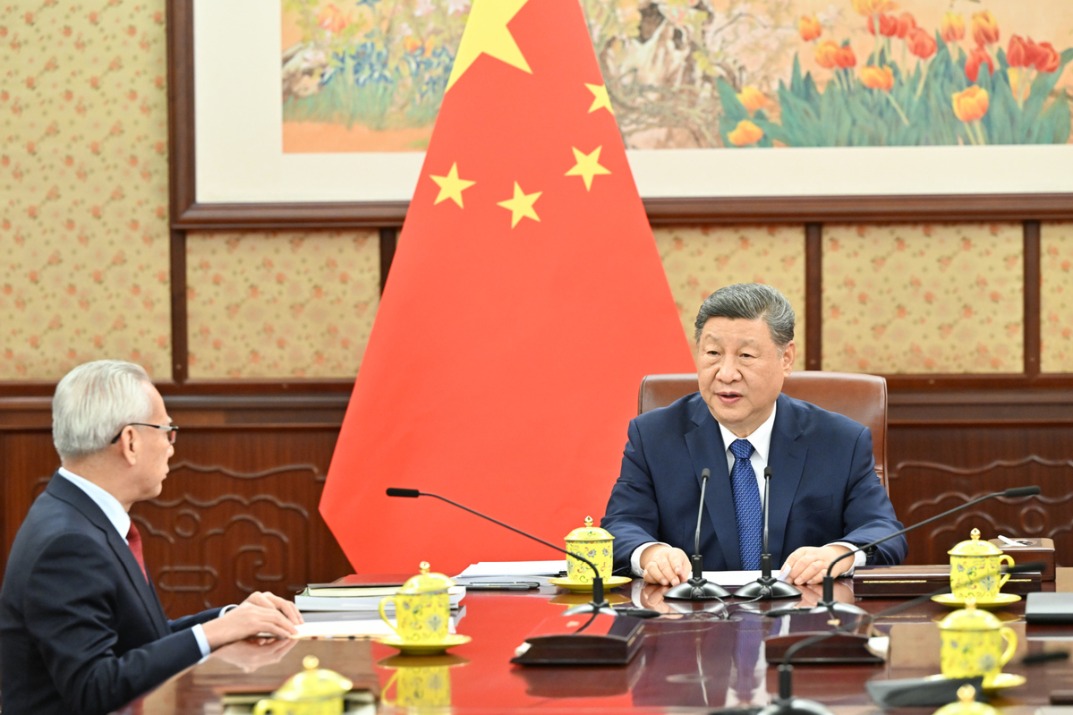

- Xi hears report from Macao SAR chief executive

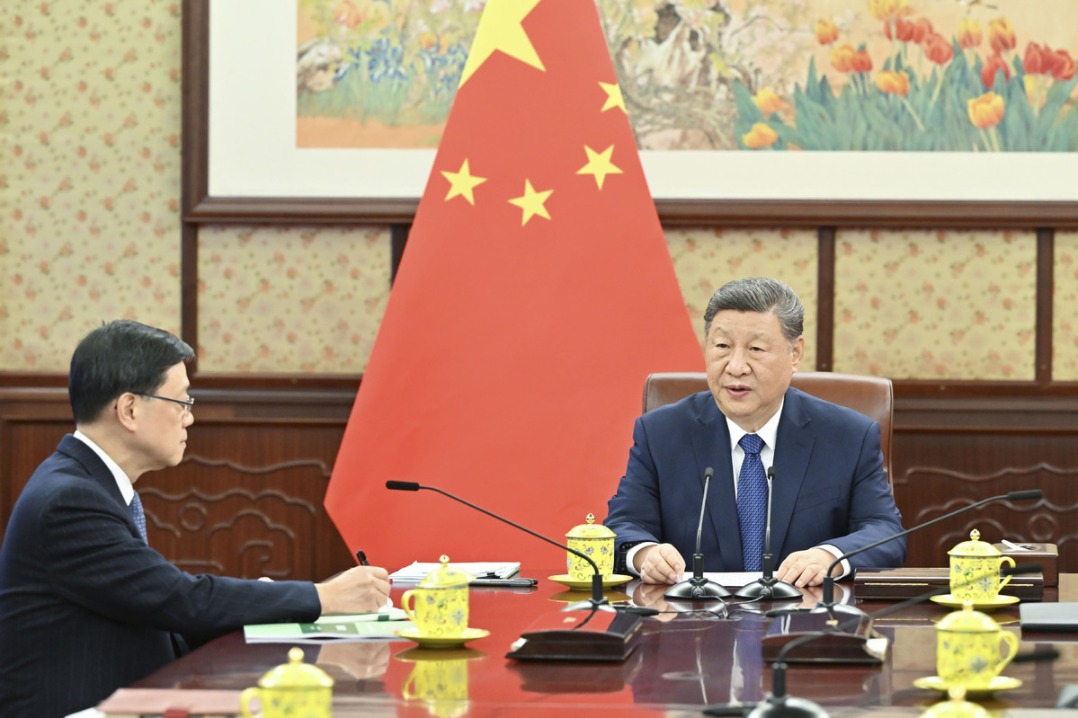

- Xi hears report from HKSAR chief executive

- UN envoy calls on Japan to retract Taiwan comments

- Innovation to give edge in frontier sectors

- Sanctions on Japan's former senior official announced

- Xi stresses importance of raising minors' moral standards