Industry toughens up in changing times

Private steel firms bank on innovation and overseas competition

The steel industry, one of the major industries in Zhangjiagang, has been facing tough times recently as the economic downturn has crimped demand for the commodity from major users, such as the real estate and automobile sectors.

Although the city is home to two of the largest privately owned steelmakers in China, Jiangsu Shagang Group and Jiangsu Yonggang Group, local companies have seen a steep erosion in product prices and profits.

"It's a lingering difficulty. It's a protracted battle," said Shen Wenrong, chairman of the Jiangsu Shagang Group, the third-largest iron and steel producer in China. "We should be prepared for a long period of painful adjustment."

But good times are just around the corner, so long as the central government applies the right guidance and adopts the appropriate policies, Shen said in a recent interview at the headquarters of his company.

Commenting on the domestic demand situation, Shen said that even in the most industrialized coastal cities, the level of prosperity is still below the level of cities in North America, Western Europe, Japan and South Korea. There is still enough room for further construction, and this in turn will stimulate demand for steel materials, he said.

Besides, the vast central and western parts of China are still in early stages of development. Their demand for steel materials will be huge, in line with their industrial ambitions for the next one or two decades.

In the international market, Shen noted, many countries in North America, the Middle East, India and Southeast Asia are still not self-sufficient in steel. When more companies start expanding abroad, they will help boost global demand for Chinese iron and steel materials.

It is here that the government can play an important role, by tailoring policies in such a way as to help Chinese steel companies avoid anti-dumping charges, Shen said.

Exports should be encouraged to redirect the surplus capacity in the country's steel industry.

Gong Sheng, executive director of Shagang, who was present at the interview, explained his company's recent efforts to adopt new technologies to boost productivity and competitiveness.

The company has been making its own five-year plans and right now it is in its ninth five-year plan, Gong said. "We are strengthening our position in both the international and domestic markets. But the international market is our main priority."

At present, Shagang sells 70 percent of its products domestically and also exports to 60 countries and regions. In 2014, it exported 4.6 million tons of steel products. This year, Gong expects Shagang's exports will exceed 6 million metric tons, an increase of more than 30 percent.

One major advance being made in Shagang is automation and use of information technologies. At many stages, innovation is also being woven into the managerial processes, Gong said.

China's iron and steel industry witnessed dramatic development over the past three decades, expanding capacity from some 30 million tons of annual output to 1 billion tons, with the actual output reaching 800 million tons - eight times the output of the United States and accounting for more than half of the world's total output.

China's rate of self-sufficiency in steel, Shen said, has increased from around 60 percent to 98 percent.

And with continuing efforts in technological upgrading, China's iron and steel industry has achieved encouraging records in energy-saving and environmental protection. The industry's average energy consumption per ton of output has been brought down from 1.5 tons of standard coal to only 500 kilograms, or one-third of its old level.

When it comes to the discharge of industrial waste and recycling of resources, China's large steelmakers are all following good standards, and some of them are doing better than their overseas counterparts, Shen said.

At the same time there has also been no pausing of the upgrading efforts.

"Better technologies are being adopted continuously, better equipment purchased, better standards followed. This is why China's better iron and steel companies are able to win over customers despite global competition. But still more efforts are needed," Shen said, "especially in research and development, in attracting talented personnel and in managerial innovation."

Over the next five years, he said, Shagang will raise its output per worker further so that it will be among the industry's best in the world. At present, the annual output per worker in Shagang's Zhangjiagang site is more than 1,300 tons, double the national average, but still lower than the record 1,700 tons in Pohang, South Korea.

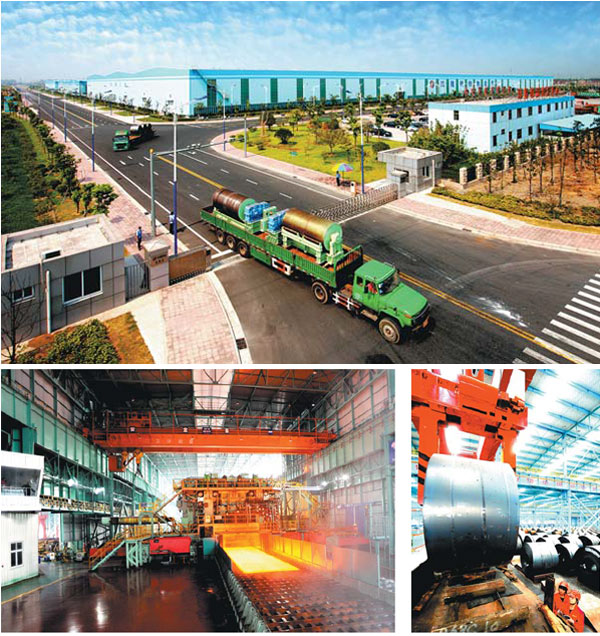

| Jiangsu Shagang Group, one of the largest privately owned steelmakers in China, exports to 60 countries and regions. |

(China Daily European Weekly 10/22/2015 page13)

Today's Top News

- Japan tempting fate if it interferes in the situation of Taiwan Strait

- Stable trade ties benefit China, US

- Experts advocate increasing scope of BRI to include soft power sectors

- New engine powers cargo drone expansion

- China to boost green industry cooperation

- Manufacturing PMI rises in November