Practically speaking

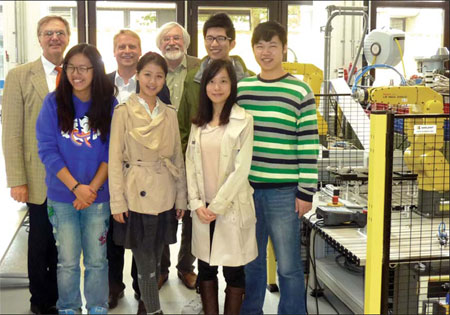

| Students at CDHAW are experiencing a new model of engineering education. Provided to China Daily |

Germans apply hands-on training to increase Chinese skills base

No matter how loud they talk tactics on the baseball field, there's a good chance the Tongji University team won't be understood by their opponents.

"Das stimmt! Because we speak in German," says Wu Sirui, a third-year engineering student at the Chinese-German University of Applied Science (CDHAW), an institute of Tongji, based in Shanghai.

Despite its dubious use as a sporting tactic, German language is one of the skills the 20-year-old and his peers learn at Tongji, a university founded by Germans in 1907. The institute, however, is better known for the quality of its practical training of engineers.

At a time when China is shifting from an export-oriented economy to one more focused on high-tech and high-end manufacturing as a model of growth, engineering students are benefiting from a Western style of practical training.

Graduates from institutes, including universities and vocational colleges, that offer such schemes are expected to fill the shortfall in China's skilled workforce.

As an educational pilot project between China and Germany, the CDHAW, founded in 2004, brought a new model of engineering education to Chinese universities. The project involves Tongji and a consortium of 26 German universities of applied sciences.

CDHAW aims to provide practical training of engineers with interdisciplinary knowledge, international competence, and the ability to find solutions for problems in the industry and economy of both countries.

CDHAW's students normally spend three years in China, and a final year in Germany, enrolled in one of Tongji's 26 partner institutes and doing internships in local companies.

"Here we talk about 'applied' engineers," says Feng Xiao, director of the CDHAW. "What distinguishes us is that our trained engineers will be able to do actual work on the first day when they join a company."

He says the focus on their courses is practice, meaning they make much more use of laboratories compared with other institutes and universities.

"We have very few lectures," Feng says. "Almost all the classes are seminars. Some courses are taught directly in the labs."

"Our priority is not training top research engineers, but those who can actually resolve problems," he says, adding that China still lags far behind countries like Germany in practical training in engineering.

The CDHAW has 30 Chinese teachers, including 10 lab engineers, and about 10 German teachers. It recruits 180 students each year.

Shortage in skilled workers has increasingly become a challenge for China with the country's change of growth model in recent years.

Foreign companies, particularly high-end manufacturers, are facing greater difficulty in recruiting such workers, and joint practical training schemes are expected to offer them more choice to meet their demand for skills.

Students in vocational schools also benefit from joint projects.

"I wouldn't have gained so much practical experience if I hadn't entered this program," says Wang Ning, 20, a second-year mold-making student at the Sino-German class of Jinan Vocational Training College in East China's Shandong province.

Only 50 of the college's 8,000 students attend the center.

While most other students attend lectures on campus, Wang spends most of her time at the newly opened vocational training center of the German company Festo, a leading supplier of pneumatic and electrical automation technology.

She works each day from 8 am to 5 pm in the workshop, making components under Festo's tutelage, rather than the college's.

"College teachers lecture us on every process and we learn," says Wang. "But here my trainer asks me to think more. I even design the process and the workflow by myself. He is like a director, giving suggestions only when I can't find out the answers myself."

Being encouraged to think and having more time to think is the key difference between vocational training in China and Germany, according to her trainer, Li Lei.

"Technology is one thing, but the key is the way of thinking," says Li, 34, who began working for Festo in 1998.

He did 40 days of training at the company's German headquarters before becoming a trainer himself, one of six in Jinan. He's now in charge of Wang and 27 other Festo apprentices.

Li says asking his apprentices to think more and organize their own workflow will help them find the answers to many questions that arise in their work process.

Traditionally, he claims, in vocational training in China teachers just teach and students just learn - but often they're not sure why.

zhanghaizhou@chinadaily.com.cn

(China Daily 11/09/2012 page13)

Today's Top News

- Xi stresses improving long-term mechanisms for cyberspace governance

- Experts share ideas on advancing human rights

- Japan PM's remarks on Taiwan send severely wrong signal

- Key steps to boost RMB's intl standing highlighted

- Sustained fight against corruption urged

- Xi calls for promotion of spirit of volunteerism